-

LATEST NEWS / PRODUCT & TECHNOLOGY1 Min Read

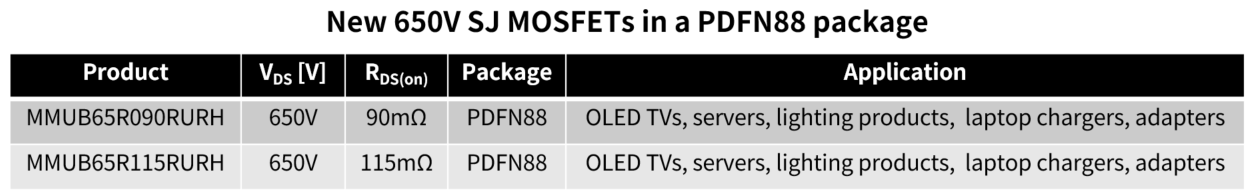

Magnachip Semiconductor Corporation announced that the Company has begun mass production of two new 650V Super Junction Metal-Oxide-Semiconductor Field-Effect Transistors (SJ MOSFETs) offerings.

These two 650V SJ MOSFETs (MMUB65R090RURH, MMUB65R115RURH) utilize an innovative PDFN88 package, which significantly reduces their thickness and size. The thickness has been reduced by approximately 81% compared to D2PAK products and 63% compared to DPAK products, while the overall footprint has been reduced to about 41% of D2PAK SJ MOSFETs.

These new SJ MOSFETs — upgraded by the PDFN88 package — offer excellent design flexibility, efficient heat dissipation, and low RDS(on) (the resistance value between the drain and the source of MOSFETs during on-state operation) characteristics. As a result, they are well-suited for various applications that require compact size and high efficiency, such as OLED TVs, servers, lighting products, laptop chargers and adapters.

“Magnachip will continue to develop high-performance power solutions enhanced by new packaging technology, building upon the successful mass production of these 650V SJ MOSFET products,” said YJ Kim, CEO of Magnachip. “We aim to drive expansion in the electronics market through our extended product portfolio and rigorous quality control.”

Original – Magnachip Semiconductor

-

Littelfuse, Inc. reported financial results for the third quarter ended September 30, 2023:

- Net sales of $607.1 million were down 8% versus the prior year period, and down 11% organically.

- GAAP diluted EPS was $2.30; adjusted diluted EPS was $2.97.

- Cash flow from operations was $161.5 million and free cash flow was $139.8 million.

“In the third quarter, sales and earnings exceeded our expectations, despite pockets of end market softness and ongoing inventory destocking,” said Dave Heinzmann, Littelfuse President and Chief Executive Officer. “Our year-to-date performance underscores the resilience of our business model, strong cash generation, and consistent execution.

Looking ahead, while dynamic macro conditions likely persist, our improved cost structure, healthy balance sheet, and ability to optimize cash flow should position us well into 2024. Our experienced team will continue to leverage our competitive advantages across our evolving and diversified end markets.”

Fourth Quarter of 2023

Based on current market conditions, for the fourth quarter the company expects,- Net sales in the range of $520 to $550 million, adjusted diluted EPS in the range of $1.90 to $2.10 and an adjusted effective tax rate of approximately 18%.

Original – Littelfuse

-

Navitas Semiconductor announced another GaNFast win at Samsung, this time a new 25W charger for the flagship Galaxy S23 smartphone. Gallium nitride (GaN) is a next-gen power-semi technology that is replacing legacy silicon chips in markets from mobile and consumer to data center, solar and EV.

The high-spec Galaxy S23 features a Dynamic AMOLED 2X, 120Hz screen with 1750 nits peak contrast, stretching it’s 1080 x 2340 pixels across 90.1 cm2 of Corning Gorilla Glass. With a Qualcomm Snapdragon 8 Gen 2 chip, up to 512GB / 8GB RAM of storage and triple cameras up to 50 MP, the S23 excels in mobile communication performance.

For power, the S23 features a 3900 mAh Li-Ion battery, and with the GaNFast 25W charger (model EP-T2510) with USB PD 3.0 interface, reaches 50% charge in only 30 minutes, and while in sleep mode, consumes only 5 mW of power. The PD 3.0 specification means that the new charger can power a range of devices from Galaxy Buds2 audio to Galaxy Z Fold5, Galaxy Flip and Galaxy A23.

Navitas’ GaNFast technology is used in a high-frequency, quasi-resonant (HFQR) topology running at 150 kHz. GaNFast leading-edge, high-frequency performance shrinks the charger by more than 30%, and the Navitas device is fully qualified to Samsung’s stringent qualification requirements, with excellent delivery performance, quality and reliability.

“As pioneers in mobile fast charging, Navitas continues to lead the next-gen market, with all 10 of the top 10 mobile OEMs in production with GaNFast products,” said David Carroll, Sr. VP Worldwide Sales. “From 25 W to 20 MW, our expanding range of leading-edge GaN and SiC products cover everything from mobile and consumer to EVs, solar and industrial applications.”

Original – Navitas Semiconductor

-

STMicroelectronics is holding its first-ever ST Taiwan Tech Day at the Taipei New Horizon on November 2. The event is designed to provide valued customers and partners with the most up-to-date information on ST products and solutions to facilitate innovation and achieve success.

With the theme “Our Technology Starts with You,” this extensive technology event will offer insightful speeches and showcase over 40 demonstrations centered around four mega trends: Smart Mobility, Power & Energy, IoT & Connectivity, and Sensing the World. Attendees can experience first-hand the latest innovations and learn how ST’s technologies are contributing to a safer, greener, and more connected world. It will also be a great opportunity to help developers and innovators stay ahead of the curve in today’s rapidly evolving market.

Innovation highlights

Smart Mobility

Zonal Gateway: Zonal Gateway acts as a bridge between the automotive central computer and traditional signal-based ECUs. This technology is supported by ST’s wide range of automotive-grade products and enables Service-Oriented Architecture (SOA) with Data Distribution Service (DDS) protocol and Firmware Over-The-Air (FOTA). The Zonal Gateway offers a solution for modernizing automotive systems, allowing for seamless communication between different components and enabling efficient and secure updates.3rd-Generation SiC Modules: The industry leader in Silicon Carbide (SiC), ST offers a wide range of solutions to help developers improve the power efficiency and reduce the size and weight of automotive inverters with its 3rd-generation SiC modules. The traction inverter is a critical component in electric vehicles as it converts energy from the battery to drive the motors in the drivetrain.

These converters must handle high power and currents, provide fail-safe operation, and handle EMC challenges. Alongside the SiC modules, ST’s range of solutions includes AEC-Q101 qualified IGBTs, silicon and silicon-carbide MOSFETs and diodes, AEC-Q100 qualified galvanically isolated IGBT and MOSFET gate drivers, and SPC5 32-bit automotive microcontrollers. These offerings enable scalable, cost-effective, and energy-efficient EV traction inverter solutions.

Power & Energy

Digital Power: ST’s digital power solution is a comprehensive set of reference designs that empower designers to create efficient, feature-rich power supplies for a wide range of applications. The demo highlights two powerful solutions: the 25kW DAB DC/DC converter with ST’s ACEPACK module, a highly efficient and reliable power converter ideal for industrial and automotive applications, and the 30kW Gen3 SiC MOSFET three-phase interleaved LLC solution with an STM32G4 MCU for ultra-high voltage EV charger — a cutting-edge power supply designed to provide ultra-fast charging for electric vehicles.With these solutions, designers can create custom power systems that are efficient, reliable, and tailored to their specific needs.

Precision Position Control: ST is a leading technology provider for motor control and servo drives, offering power device technologies, computational processing, isolated devices, industrial safety, ecosystem for industrial automation, connectivity, and predictive maintenance. With ST’s state-of-the-art motor-control technologies, the motor can precisely control movement to a specific position.

The demo consists of two small BLDC motors that can hold two shapes that do not fit together when they are in phase. The precision motor-control algorithm enables the rotation and movement of the shapes towards each other at any time, offsetting the relative position of the two shapes by 90 degrees while rotating. This unique position allows coupling between the shapes, with a rotation speed that ensures the phase shift is not noticeable, demonstrating precision position control in a harmonic movement coordinated simultaneously with other shapes.

IoT & Connectivity

Edge AI Washing Machine Solution: This solution utilizes artificial intelligence (AI) to achieve unparalleled levels of energy and water efficiency by accurately measuring the weight of clothes inside the machine. The AI model generated by ST’s NanoEdge AI Studio significantly improves measurement accuracy compared to traditional algorithms by analyzing and learning the features of current signals. This technology can advance the washing-machine industry to a next level by optimizing energy and water consumption while providing more accurate measurements.Compact Production Line with IO-Link System: The IO-Link automated product line demonstrates ST’s total solution application in a smart factory, utilizing IO-Link technology to manage digital input/output, sensors, and solenoid air valve drivers. The demos include digital IO boards, sensor boards, and actuator boards from ST’s Automation Competence Center’s reference demo boards. The IO-Link products simplify the installation, setup, maintenance, and repair of factory automation systems, enhancing system flexibility to produce different product models. The IO-Link diagnostic function enables smarter and more reliable factory operations.

Sensing the World

3D Sensing Solutions: ST showcases the advanced imaging capabilities of the 3D stereo-vision camera solutions for machine-vision applications. The eYs3D stereo camera reference design features ST’s high-performance, near-infrared VD56G3 global-shutter image sensors, ensuring the highest quality depth sensing and point-cloud creation.Additionally, the VD55H1 low-noise, low-power, indirect Time-of-Flight (iToF) sensor die, manufactured using advanced backside-illuminated, stacked-wafer technology, enables the creation of a small form-factor 3D camera capable of producing high-definition depth maps with a typical ranging distance of up to 5 meters in full resolution and beyond 5 meters with patterned illumination. This demo highlights ST’s commitment to providing cutting-edge technology for machine-vision applications.

ISPU for personal electronics: ISPU (Intelligent Sensor Processing Unit) is a new processing category embedded in ST’s LSM6DSO16IS MEMS module. It is an ultra-low-power, high-performance programmable core that can execute signal processing and AI algorithms in real-time. The ISPU offers C programming and an enhanced ecosystem with libraries and 3rd-party tools/IDE, making it a state-of-the-art feature for any personal electronics.

In addition to the insightful speeches and exciting technology showcase, more than 20 in-depth technical presentations covering Smart Mobility, Power and Energy, and IoT and Connectivity will provide a close look at the cutting-edge technologies that are shaping our world.

To learn more about the exciting demos and program, please visit the ST Taiwan Tech Day event page.

Original – STMicroelectronics

-

LATEST NEWS1 Min Read

Mitsubishi Electric Corporation announced its consolidated financial results for the first half and second quarter, ended September 30, 2023, of the current fiscal year ending March 31, 2024 (fiscal 2024).

Consolidated Half-year Results (April 1, 2023 – September 30, 2023)

- Revenue: 2,538.4 billion yen (9% increase year-on-year)

- Operating profit: 135.8 billion yen (69% increase year-on-year)

- Profit before income taxes: 159.7 billion yen (55% increase year-on-year)

- Net profit attributable to Mitsubishi Electric Corp. stockholders: 120.2 billion yen (61% increase year-on-year)

The economy in the first half, from April through September 2023, of fiscal 2024 continued to see recovery primarily in consumer spending despite monetary tightening and other factors in the U.S. In Japan, the economy continued to see moderate recovery due to robust consumer spending and an increase in inbound tourists.

In China, the economy showed weakness in recovery due to sluggish export as well asslower domestic demand resulting from the real estate recession and other factors. In Europe, there were slowdowns in the corporate and household sectors due to monetary tightening and other factors.

Original – Mitsubishi Electric

-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / WBG4 Min Read

A cross-organizational team from Rigaku SE and Fraunhofer IISB has established a new semicon-ductor material characterization method in their jointly operated Center of Expertise for X-ray Topography in Erlangen, Germany. They succeeded not only in developing an industry-ready X-ray topography system, but also in employing defect detection and quantification algorithms, achieving a worldwide unique material characterization method for silicon carbide (SiC) wafers.

SiC is an excellent semiconductor for application areas like electric mobility and transportation, sustainable energy supply, industrial infrastructure up to sensors and quantum technologies even under harsh operating conditions.

As representatives for the whole research team, Dr. Kranert and Dr. Reimann from Fraunhofer IISB and Dr. Hippler, Managing Director Rigaku Europe SE, have won the Georg Waeber Innovation Award 2023 from the Förderkreis für die Mikroelektronik e.V. (Microelectronics Promotion Society).

Pioneering holistic material defect characterization with X-ray topography

In 2021, Rigaku SE and Fraunhofer IISB have founded the Center of Expertise for X-ray Topography, a joint lab that is located at the IISB’s headquarters in Erlangen, Germany. Here, the cross-organizational team has now developed a new metrology that is non-destructive, robust, reliable, high-throughput and therefore capable of swiftly detecting all relevant crystallographic defects in SiC substrates.

For the first time worldwirde, this innovation realized the holistic approach of setting up the measurement device, i.e., the X-ray topography (XRT) tool as well as formulating appropriate measurement and analysis routines that specifically meet the industry’s demands for speed, reliability, and accuracy. The development process was supported by rigorous scientific validation of the results, a crucial factor for the acceptance of a new approach in the industry.

Until now, no such industry-ready metrology existed for the early stages of SiC power electronics manufacturing, especially at substrate or crystal (commonly referred to as the “puck”) level. This breakthrough in SiC substrate inspection makes it no longer necessary to, e.g., destructively defect etch and discard semiconductor substrates for characterization, as is currently often the case. In consequence, the developed XRT metrology is superior to these existing substrate characterization methods employed in the industry, ultimately leading to substantial cost savings.

Effectively, this technology, developed in Germany, provides everything needed to become the industry standard for specifying and controlling substrate quality in production as well as for R&D substrate and device manufacturers worldwide. The success of this joint innovation is vividly illustrated by the new business, which Rigaku has successfully established in less than two years. Now, the Japan-based company is the world’s leading supplier of XRT tools for SiC substrate and device manufacturing.

The innovative metrology approach has been driven significantly by Dr. Michael Hippler, Managing Director of Rigaku Europe SE, and Dr. Christian Kranert with Dr. Christian Reimann, both group managers in the Fraunhofer IISB’s Materials department. Hence the scientists were selected for the Georg Waeber Innovation Award 2023 by the Förderkreis für die Mikroelektronik e.V. (Microelectronics Promotion Society).

The Förderkreis is an association of industry companies, two Fraunhofer institutes, four chairs of the University of Erlangen-Nuremberg and the Nuremberg Chamber of Commerce and Industry. The main objective is to foster a smooth exchange between science and industry, which is manifested in the Georg Waeber Innovation Award. The award is presented annually for outstanding scientific achievements and places a strong emphasis on the advancement of knowledge in microelectronics and its practical application in the industry. On October 25, 2023, Dr. Hippler, Dr. Reimann and Dr. Kranert received the award during a ceremony at Fraunhofer IISB in Erlangen.

Paving the way for the next generation of SiC power electronics

SiC semiconductor devices play a pivotal role in the power electronics industry. As a replacement for conventional silicon-based power electronics, SiC has the potential to enhance energy efficiency while reducing system costs. It is relevant across various application areas from electric mobility and transportation, sustainable energy supply, industrial infrastructure up to sensors and quantum technologies even under harsh operating conditions.

Consequently, processing low-cost, energy-efficient, and highly reliable SiC power devices is a critical endeavor with the worldwide electrification trend. The production capacities for SiC wafers experience significant growth, which goes hand in hand with an increasing demand for wafer inspection and metrology within the SiC industry. In particular, manufacturers of substrates and power devices require precice information regarding the quality of substrates in terms of crystallographic defects, their distribution across the entire wafer area, and absolute quantities.

Original – Fraunhofer IISB

-

DENSO announced global financial results for its second quarter, ending September 30, 2023, for its 2024 fiscal year, ending March 31, 2024:

- Consolidated revenue totaled 3,513.5 billion yen (US$23.5 billion), a 16.3 percent increase from the previous year.

- Consolidated operating profit totaled 211.8 billion yen (US$1.4 billion), a 36.3 percent increase from the previous year.

- Consolidated profit attributable to owners of the parent company totaled 168.9 billion yen

(US$1.1billion), a 59.7 percent increase from the previous year.

“Revenue in the second quarter increased compared to the previous year due to the strong vehicle sales mainly in Japan and North America, foreign exchange gains and expansion of products for electrification, safety and peace of mind areas though decrease of Japanese, European, and American vehicle sales in China.

Operating profit in the second quarter increased compared to the previous year due to production volume, foreign exchange gains and improvement, though the continuing rise in the cost of materials, especially electronic components, and the accelerating investment for future as R&D.” said Yasushi Matsui, CFO, Vice President and member of the Board of Directors of DENSO CORPORATION.

“In this fiscal year, we forecast 7,000.0 billion yen (US$46.8 billion) in revenue and 630.0 billion yen (US$4.2 billion) in operating profit. Revenue and operating profit will be based on strong sales actuals in the first half and forecast of foreign exchange gains and sales expansions in the third quarter. The annual dividends for the end of the fiscal year will be 52 yen, a 2 yen increase from the previous announcement. This means 208 yen as pre-stock split conversion. We will continue to improve DOE levels over the long term and in a stable manner.”

In Japan, revenue increased to 2061.2 billion yen (US$13.8 billion), up 18.5% from the previous year, and operating profit was 85.2 billion yen (US$569.5 million), down 6.4% from the previous year.

In North America, revenue increased to 856.6 billion yen (US$5.7 billion), up 19.8% from the previous year, and operating profit was 14.2 billion yen (US$94.8 million) (Operating loss of 13.0 billion yen in the same quarter of the previous year).

In Europe, revenue increased to 372.8 billion yen (US$2.5 billion), up 15.8% from the previous year, and operating profit was 13.9 billion yen (US$92.8 million), up 285.0% from the previous year.

In Asia, revenue increased to 974.0 billion yen (US$6.5 billion), up 1.4% from the previous year and operating profit was 88.2 billion yen (US$589.6 million), up 30.9% from the previous year.

In other areas, revenue increased to 60.3 billion yen (US$0.4 billion), up 12.4% from the previous year, and operating profit was 11.5 billion yen (US$76.9 million), up 0.8% from the previous year.

Forecast for Fiscal Year Ending March 31, 2024

Full-Year Forecast Changes from Previous Forecast Revenue 7,000.0 billion yen

[US$46.8 billion]+300.0 billion yen

(+4.5 percent)Operating profit 630.0 billion yen

[US$4.2 billion]+30.0 billion yen

(+5.0 percent)Profit before profit taxes 684.0 billion yen

[US$4.6 billion]+30.0 billion yen

(+4.6 percent)Profit attributable to owners

of the parent company470.0 billion yen

[US$3.1 billion]+26.0 billion yen

(+5.9 percent)ROE 9.7% +0.4% Original – DENSO