-

Vincotech is returning to PCIM, the world’s leading power electronics expo and conference to showcase its latest technologies and innovations, including GaN and many more products for Motion Control, Renewable and Power Supply use cases. In keeping with this year’s expo slogan “Empowering your ideas,” the company’s application-specific capabilities will be on prominent display.

Highly anticipated, PCIM Europe event is sure to draw thousands of visitors, and Vincotech is thrilled to be back. “Our fair booth will feature all kinds of new tech, and we can’t wait to show customers and prospects how our solutions benefit their business. Hot topics, innovations, donations – expect all that and more”, says Edoardo Guiotto, VP Sales and Marketing.

This year’s big talking point is the company’s commitment to application-specific solutions enabled by a wide range of industrystandard and proprietary housings, multi-source chipsets, expedited time-to-market, and early sample availability. Highlights include a solution for SEW-EURODRIVE, showcased with a station displayed at the booth.

- One spotlight will be on GaN, a cutting-edge technology that has the industry abuzz. Vincotech, which is driving advances on this front, is going to demonstrate the potential, benefits, and applications of GaN in power modules.

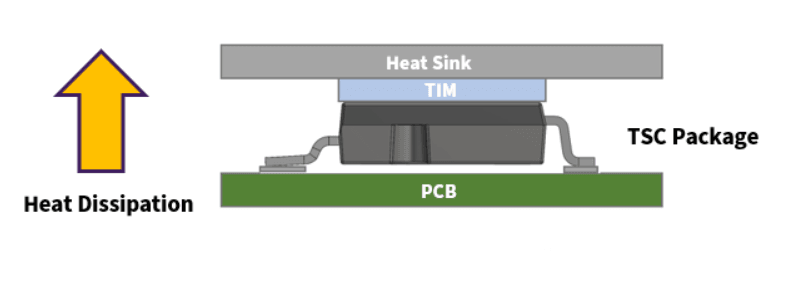

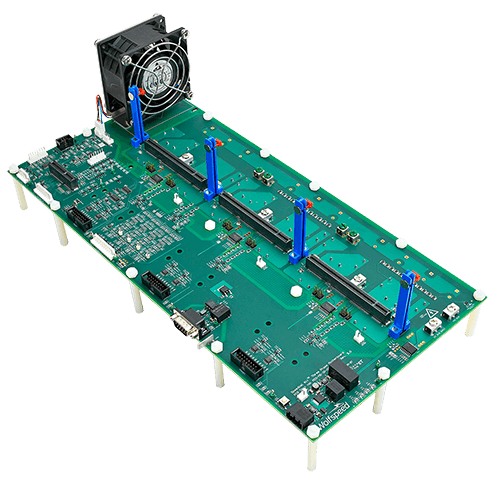

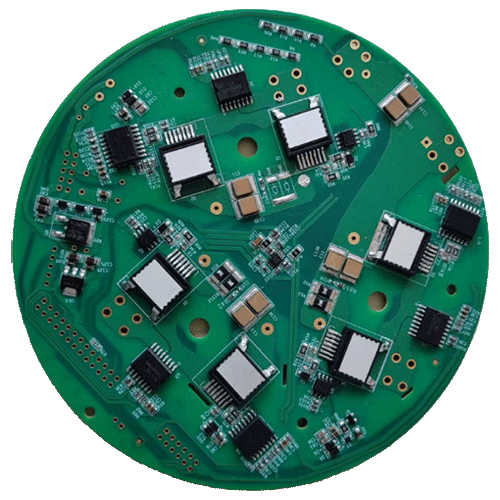

- Innovations in motor control applications will also figure prominently. Reliability and performance packed into a small footprint – that’s what sophisticated motor control use cases need. Highly integrated and engineered to support complex electrical and thermal designs, Vincotech’s embedded drive solutions meet these demands. For Industrial drives the tandem diode solutions are available for SixPack, Twin SixPack and PIM topologies including custom and industry standard power module housings.

- Renewables are on the rise. Built on decades of experience in solar, Vincotech’s extensive portfolio of PV & ESS solutions is second to none. Residential, industrial, commercial – every use case and power range is well-covered.

- Leading the way in power supply, Vincotech offers outstanding power module solutions. Highlights in DC fast charging include a built-to-boost 3-phase resonant converter, the fastPACK 1 GaN 2-in-1 featuring advanced Wide Bandgap (WBG) tech, and many ultra-compact, integrated solutions and low inductive modules. Enhancing the performance of Uninterruptible Power Supplies (UPS), Vincotech has a wide range of solutions from 20 kW – 250 kW power.

Like in previous years, Vincotech teams up with Plan International Germany, bringing an exciting VR experience to the event. Visitors can challenge themselves by flying over the mountains in virtual reality, while knowing their participation supports a greater good. Vincotech will match all flights with a donation, targeting a Plan International project for teenagers in Ecuador.

Vincotech’s PCIM presentations at a glance:

Tuesday, June 11

11:15 Exhibitor forum

David Chilachava: NEW fastPACK 1 GaN – The Best Utilization of GaN Technology Benefits in an Industrial Power Module PackageWednesday, June 12

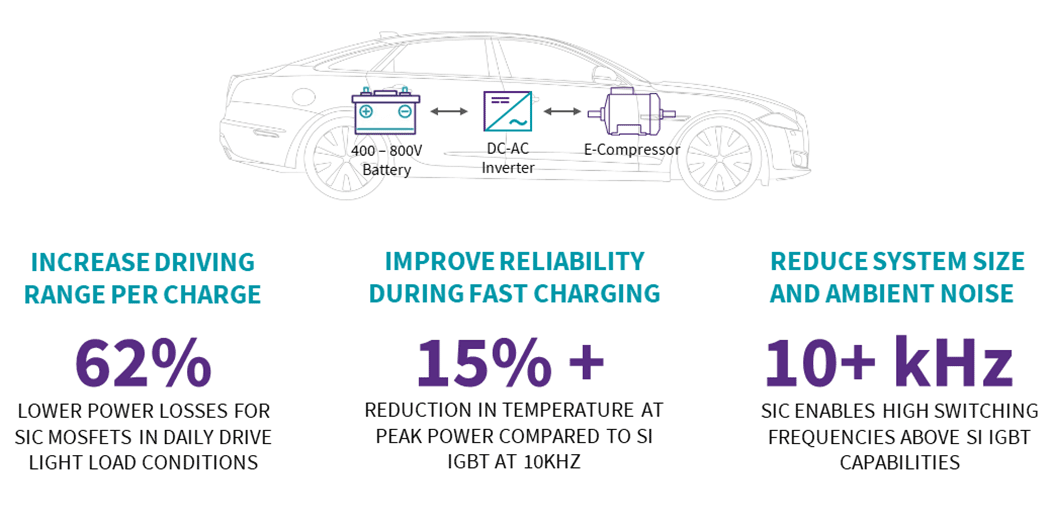

11:20 Bodo’s panel discussion on “SiC Wide Bandgap Design, the Future of Power”)

Evangelos Theodossiu: SiC power module design: Why does it matter?

14:30 Conference, Room: München 2

A joint presentation with Siemens: Optimizing a Power Module for Electrical and Thermal Performance and Symmetry Using EDA ToolsThursday June 13

11:15 Conference poster sessions

Tiago Jappe: Power Module Solutions with Improved Reliability for Elevator Drive Applications

14:35 Exhibitor forum

Matthias Tauer: flow E3 Full SiC Power Module with Direct Pressed Substrate for Superior Thermal Performance and ReliabilityOriginal – Vincotech