-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / WBG3 Min Read

Power Master Semiconductor has announced the expansion of its e SiC MOSFET family with introduction of new AEC-Q101 qualified, high-performance top-side cooling packages. These include the TSPAK DBC version and LF version, specially designed for automotive and industrial applications.

The TSPAK offers superior thermal performance, high efficiency, power density and reliability, making it ideal for a variety of automotive applications such as on-board chargers (OBCs), DC-DC converters, and e-compressors. This innovative packaging leverages Power Master Semiconductor’s latest generation of 1200V eSiC MOSFET (Gen2), employing cutting-edge technology to decouple a trade-off between specific on-resistance (Rsp) and short-circuit withstand time (SCWT). Compared to the previous generation, the new 1200V eSiC MOSFETs deliver 20% reduction in RDS(ON) and a 15% improvement in SCWT, as well as a 45% reduction in switching losses.

Key Features and Benefits of TSPAK

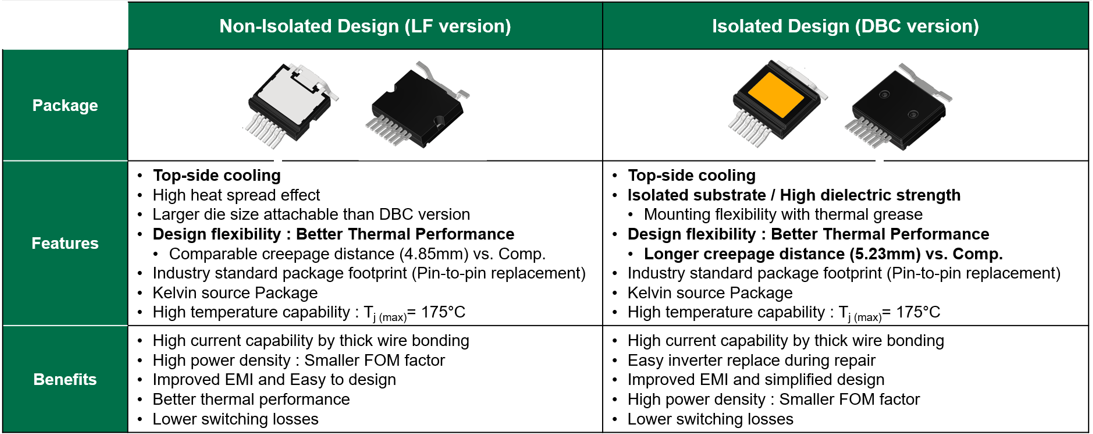

TSPAK LF version

- Top-side cooling package with an exposed drain at the surface, allowing direct heat dissipation to the heatsink.

- Offers superior thermal performance and supports high current capabilities.

- High temperature capability : Tj (max)= 175°C

TSPAK DBC version

- Integrates an isolated DBC ceramic pad on the surface, providing premium thermal performance and enhanced design flexibility.

- Features 3.6kV isolation voltage, extended creepage distance (5.23mm), and flexible mounting by directly connected to an external heatsink with thermal grease.

- High temperature capability : Tj (max)= 175°C

With an industry-standard footprint of 14mm x 18.58mm, the TSPAK packages provide superior thermal performance and Kelvin source configuration to minimizes gate noise and reduces turn-on losses by 60%, enabling higher-frequency operation and improved power density.

The PCR120N40M2A (LF version) and PCRZ120N40M2A (DBC version) are automotive-grade 1200V/40mΩ eSiC MOSFETs in TSPAK packages, leveraging Power Master Semiconductor’s 2nd-generation eSiC MOSFET technology to deliver optimized performance for the automotive systems.

- E-compressors, vital for efficient thermal management, extended battery life, enhanced charging efficiency, and improved driving range.

- Totem-Pole PFC and CLLC/DAB (Dual Active Bridge) topologies, essential for bidirectional power conversion in 800V battery systems used in electric vehicles.

“Cooling is one of the greatest challenges in high power design and successfully addressing it is the key enabler to reducing size and weight, which is critical in modern automotive design” said Namjin Kim, Senior Director of Sales & Marketing. “Our new top-side cooling package offer better system efficiency and minimize heat thermal path on the PCB, the system design will be simplified and compacted. We are confident that this innovative solution will be the optimal choice for high-performance automotive applications.”

“Efficient cooling is a critical challenge for reducing size and weight of high-power automotive systems,” said Namjin Kim, Senior Director of Sales & Marketing. “Our new top-side cooling package enhances system efficiency and minimizes the thermal path on the PCB, enabling simpler, more compact system designs. We believe this innovative solution will drive the high performance automotive applications.”

Original – Power Master Semiconductor

-

Infineon Technologies AG has won the German Sustainability Award in the “Electrical Engineering and Electronics” category. “The jury is of the opinion that Infineon has assumed a leading role in the field of sustainability and serves the sector as a ‘beacon’ for successful transformation,” the judges said in their statement. The German Sustainability Award recognizes companies which make effective and exemplary contributions to transformation and which function as role models within their industry.

“We are particularly honored and delighted to win the German Sustainability Award,” said Elke Reichart, Member of the Management Board and Chief Digital and Sustainability Officer at Infineon, who accepted the award in Duesseldorf. “We at Infineon work hard to drive decarbonization and digitalization and to create a more sustainable future. This award is recognition, as well as an incentive to be a role model in sustainability and to continue rigorously implementing our ambitious sustainability strategy – together with our employees, customers and partners.”

Infineon is pursuing a comprehensive and ambitious decarbonization strategy. The company is making good progress towards the goal it defined in 2020: achieving climate neutrality by 2030. Since then, emissions have been reduced by more than two thirds while revenue has almost doubled. Moreover, Infineon is intensifying its collaboration along the entire supply chain. As a pioneer in its industry, Infineon this year began reporting emissions at the individual product level, referred to as the Product Carbon Footprint. The data is already available for half of all Infineon products today.

Infineon’s semiconductors are decisive in making the generation, transmission, storage and use of energy more efficient. A recent example of sustainable product innovation by Infineon is a new type of energy-saving silicon carbide (SiC) module, whose developers were nominated for the 2024 Deutscher Zukunftspreis. The solution increases the energy efficiency of existing high-performance electrical applications such as solar and wind power plants and train drives. Among other things, the module also facilitates the efficient electrification of large drives such as those found in agricultural and construction machinery, ships and aircraft. In concrete terms, a single electric locomotive equipped with the new drive system saves around 300 megawatt hours per year, which corresponds to the annual energy requirements of 100 single-family homes.

The German Sustainability Award is Europe’s largest award for ecological and social commitment. The jury of the German Sustainability Award (DNP) selected winners in 100 different sectors from among around 2000 competing companies. The German Sustainability Award works together with the German Chamber of Industry and Commerce (DIHK), WWF Germany, PwC Germany, Leuphana University Lüneburg (CSM Lüneburg) and numerous other industry associations to design and implement the competition.

Current reports on sustainability at Infineon can be found here.

Original – Infineon Technologies