-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / WBG3 Min Read

Nexperia announced that it has entered into a strategic partnership with KOSTAL, a leading automotive supplier, which will enable it to produce wide bandgap (WBG) devices that more closely match the exacting requirements of automotive applications. Under the terms of this partnership, Nexperia will supply, develop, and manufacture WBG power electronics devices which will be designed-in and validated by Kostal. The collaboration will initially focus on the development of SiC MOSFETs in topside cooled (TSC) QDPAK packaging for onboard chargers (OBC) in electric vehicles (EV).

KOSTAL Automobil Elektrik, with over a century of experience, is a key player in the global automotive industry. Nearly one in every two cars worldwide is equipped with KOSTAL’s products, including more than 4.5 million onboard chargers, contributing to advancements in electromobility. Ranked among the top 100 automotive suppliers globally, KOSTAL is recognized for its innovative, reliable, and cost-optimized solutions. Its long-standing partnerships with customers and employees reflect the company’s commitment to quality and collaboration.

“Nexperia has been a trusted supplier of silicon components to KOSTAL for many years and is delighted to enter into this strategic partnership that will now extend to wide bandgap devices”, according to Katrin Feurle, Senior Director and Head of SiC Discretes & Modules. “KOSTAL will assist in validating our devices in its charging applications, thereby providing us with the type of invaluable ‘real-world’ data that will allow us to further enhance their performance”.

“KOSTAL is extending its’ strategic SiC supply portfolio to support our growth path towards 2030 with a special dedication on E-Mobility applications for onroad and offroad applications” states Dr. Georg Mohr, Executive VP Purchasing & Supply Chain of the KOSTAL Group. “Under this strategic partnership, which reinforces our long- standing customer-supplier relationship, KOSTAL will leverage Nexperia’s expertise in wide bandgap technology, particularly their SiC MOSFETs, which we believe are among the best in the market. By sharing our insights from real-world EV charging applications, we aim to contribute to the development of even more optimized and tailored SiC devices that meet the specific demands of our next-generation solutions.”

Nexperia is among the few companies that is offering a comprehensive range of WBG semiconductor technologies, including SiC diodes and MOSFETs, as well as GaN e-mode and d-mode devices, alongside its established silicon portfolio. With a strong commitment to expanding its commercial WBG offerings, Nexperia is focused on delivering the most suitable products to meet the needs of an increasing range of applications. The company’s focus is to support the responsible use of electrical energy through innovative solutions. Nexperia continues to develop technologies that address the growing demand for efficiency and sustainability in power management.

Original – Nexperia

-

FINANCIAL RESULTS / LATEST NEWS3 Min Read

Navitas Semiconductor announced unaudited financial results for the third quarter ended September 30, 2024.

“I’m pleased to announce record sales in the mobile fast-charger market plus a completely new GaN platform for 48V AI data centers, EV and AI robotics applications in conjunction with a new, strategic, dual-sourcing partnership with Infineon,” said Gene Sheridan, CEO and co-founder.

`“Despite macro-economic challenges, we continue to grow faster than the market, and the new, low-voltage GaN platform not only opens up new strategic markets, but also brings customers dual-sourcing options from Navitas and Infineon for added confidence to accelerate adoption of GaN into new mainstream, high-volume applications.”

The company also announced a cost-reduction plan that is expected to save $2 million per quarter and streamline the organization with increased focus on AI data center, EV and mobile applications, accelerating the company’s path to profitability. The plan includes a 14% reduction in headcount (approximately 45 employees).

3Q24 Financial Highlights

- Revenue: Total revenue was $21.7 million in the third quarter of 2024, compared to $22.0 million in the third quarter of 2023, and $20.5 million in the second quarter of 2024.

- Loss from Operations: GAAP loss from operations for the quarter was $29.0 million, compared to a loss of $28.6 million for the third quarter of 2023 and a loss of $31.1 million for the second quarter of 2024. On a non-GAAP basis, loss from operations for the quarter was $12.7 million compared to a loss of $8.7 million for the third quarter of 2023, and a loss of $13.3 million in the second quarter of 2024.

- Cash: Cash and cash equivalents were $98.6 million as of September 30, 2024.

Market, Customer and Technology Highlights

- New, Low-voltage (LV) GaN Platform (80-200V): Optimized for 48V systems in AI data center, EV, and motor drive, sampling in Q4 2024, with strategic dual-sourcing partnership with Infineon Technologies. Common specifications (packaging, pin-out, footprint and IP) to accelerate customer adoption of GaN into high-volume, mainstream applications.

- AI Data Center: New 98%-efficient, 8.5 kW AI power supply reference design with high-voltage (HV) GaN+SiC architecture launched as well as proprietary IntelliWeave™ PFC control technique to deliver extreme power density demanded by NVIDIA’s Hopper-Blackwell-Rubin AI GPU roadmap. High-voltage GaNSafe power ICs and Gen-3 ‘Fast’ SiC devices are featured in over 60 active customer projects with direct customers such as Delta, GreatWall, Compuware and LiteON, supplying end-users like AWS, Azure and Google. Our data center production revenues started in Q3 as expected and will continue ramping throughout 2025.

- EV: Leading-edge, trench-assisted, planar-gate Gen-3 ‘Fast’ SiC devices now fully AEC Q101 (automotive) qualified and pushing beyond. Six new on-board and road-side charger design wins in Q3, expected to ramp in 2025 and 2026. Largest pipeline segment, with 200+ projects. New, LV GaN platform optimized for 48V battery EV applications.

- Mobile & Consumer: GaNSlim ICs achieved another 26 design wins in Q3. Three new tier-1 OEM wins expected to deliver revenue ramping Q2’25, adding to the Samsung wins announced in August.

- Appliance & Industrial: Thirty new design wins in Q3, ranging from vacuum cleaners and LED lighting, to solid-state, grid-connected circuit-breakers, multi-kW power supplies and heat pumps. New, LV GaN platform addresses 48V industrial motor drives including AI robotics.

- Solar & Energy Storage: Ten design wins, including at Generac, expected to ramp mid-2025. Next-gen GaN ICs – including Navitas-proprietary, industry-leading bi-directional GaN ICs – continue on track for significant mid-2025 ramp in solar micro-inverters. New, LV GaN doubles TAM in inverters, as complement to HV GaN and SiC.

Fourth quarter 2024 net revenues are expected to be between $18.0 and $20.0 million. Non-GAAP gross margin for the fourth quarter is expected to be 40% plus or minus 50 basis points and non-GAAP operating expenses are expected to be approximately $20.5 million in the fourth quarter of 2024.

Original – Navitas Semiconductor

-

NXP Semiconductors N.V. reported financial results for the third quarter, which ended September 29, 2024.

“NXP delivered quarterly revenue of $3.25 billion, in-line with our overall guidance. While we experienced some strength against our expectations in the Communication Infrastructure, Mobile and Automotive end markets, we were confronted with increasing macro related weakness in the Industrial & IoT market. Our guidance for the fourth quarter reflects broader macro weakness especially in Europe and the Americas. We focus on managing what is in our control enabling NXP to drive resilient profitability and earnings in an uncertain demand environment,” said Kurt Sievers, NXP President and Chief Executive Officer.

Key Highlights for the Third Quarter 2024:

- Revenue was $3.25 billion, down 5 percent year-on-year;

- GAAP gross margin was 57.4 percent, GAAP operating margin was 30.5 percent and GAAP diluted Net Income per Share was $2.79;

- Non-GAAP gross margin was 58.2 percent, non-GAAP operating margin was 35.5 percent, and non-GAAP diluted Net Income per Share was $3.45;

- Cash flow from operations was $779 million, with net capex investments of $186 million, resulting in non-GAAP free cash flow of $593 million;

- During the third quarter of 2024, NXP continued to execute its capital return policy with the payment of $259 million in cash dividends, and the repurchase of $305 million of its common shares. The total capital return of $564 million in the quarter represented 95 percent of third quarter non-GAAP free cash flow. On a trailing twelve month basis, capital return to shareholders represented $2.4 billion or 87 percent of non-GAAP free cash flow. The interim dividend for the third quarter 2024 was paid in cash on October 9, 2024 to shareholders of record as of September 12, 2024. On August 29th, the NXP board of directors authorized an additional $2.0 billion for share repurchases, resulting in a $2.64 billion share repurchase balance at the end of the third quarter. Subsequent to the end of the third quarter, between September 30, 2024 and November 1, 2024, NXP executed via a 10b5-1 program additional share repurchases totaling $117 million;

- On August 20, 2024, ESMC, the previously announced manufacturing joint venture between TSMC, Robert Bosch GmbH, Infineon Technologies AG and NXP Semiconductors N.V. held a groundbreaking ceremony to mark the initial phase of construction of its first semiconductor fab in Dresden, Germany;

- On September 4, 2024, Vanguard International Semiconductor Corporation and NXP Semiconductors N.V. announced the receipt of all necessary governmental approvals from relevant authorities and injected capital to officially establish the previously announced VisionPower Semiconductor Manufacturing Company Pte Ltd (VSMC) manufacturing joint venture. The company will now proceed with the planned construction of VSMC’s first 300mm wafer manufacturing facility;

- On September 10, 2024, NXP announced the Trimension® SR250, the industry’s first single-chip, UWB solution to enable Industrial and IoT applications that integrates on-chip processing capabilities with both short-range UWB-based radar and secure ranging;

- On September 17, 2024, NXP announced the MC33777, the world’s first electric vehicle battery junction box IC that consolidates essential BMS functions into a single device; and

- On September 24, 2024, NXP announced the new i.MX RT700 crossover MCU family, designed to power smart AI-enabled edge devices, such as wearables, consumer medical devices, smart home devices and HMI platforms.

Original – NXP Semiconductors

-

GaN / LATEST NEWS / WBG3 Min Read

Cambridge GaN Devices (CGD) will exhibit at Electronica which runs from November 12-15, 2024 at the Messe München, Munich, Germany. This will be the second time that the company has exhibited at the world’s leading trade fair and conference for electronics, marking the company’s position as a leader in delivering gallium-nitride power ICs which are easy to use and very reliable.

ANDREA BRICCONI | CHIEF MARKETING OFFICER, CGD

“Since our first appearance at Electronica, CGD has made remarkable steps. We have introduced our P2 series ICeGaN® ICs that feature RDS(on) levels down to 25 mΩ, supporting multi kW power levels with the highest efficiency. We have announced a deal with TSMC, the leading IC fabrication house in the world which ensures quality and supply of our innovative power devices. Also, studies by leading academic research establishment, Virginia Tech University, have demonstrated that our ICeGaN GaN technology is more reliable and robust than other GaN platforms. GaN is now available for use at higher power levels, and at Electronica we are expecting to meet with designers who are eager to take advantage of the efficiency and power density benefits that GaN can bring to their latest designs.”During the show, CGD will make two presentations:

- November 12, 13:20 – 14:10, Booth A5.351: SiC & GaN Technologies – Exploring Advancements, Addressing Challenges CGD’s CTO and co-founder, Professor Florin Udrea will join a panel of GaN experts for a Panel Discussion moderated by Maurizio Di Paolo Emilio, Editor-in-Chief, Power Electronics News.

- November 12, 16:10-16:35, Power Electronics Forum: ICeGaN as a smart high voltage platform for high power industrial and automotive applications presented by Professor Florin Udrea.

The power devices field has undergone significant change due to the emergence of Wide Band Gap semiconductors, particularly Gallium Nitride (GaN) and Silicon Carbide (SiC). Traditionally, GaN has been used for lower power consumer applications (e.g., power supplies), while SiC dominated the medium to high power markets, such as industrial (e.g., motor drives) and automotive applications (e.g., traction inverters).

SiC’s superior scaling of on-state resistance at high voltages gives it an edge above 1.2 kV, but GaN is now competing with SiC at 650V for all power levels. ICeGaN®, featuring sensing and protection functions, surpasses discrete SiC in terms of robustness and ease of paralleling, offering notable advantages for 650V high-power applications. Additionally, with the rise of multi-level topologies for traction inverters, GaN may challenge SiC’s 1.2 kV market. Ultimately, both technologies have a bright future, with overlap expected in high-power (10-500 kW) applications.

At Electronica, CGD will show a number of demos that employ ICeGaN, including:

- 3 kW totem-pole PFC evaluation board;

- High and low power QORVO motor drive evaluation kits developed in collaboration with CGD and utilising ICeGaN

- Half-bridge and full-bridge evaluation boards, plus an ICeGaN in parallel evaluation board;

- Single leg of a 3-phase 800 V automotive inverter demo board, developed in partnership with French public R&I institute, IFP Energies nouvelles (IFPEN);

- ICeGaN vs discrete GaN circuits comparison in half bridge (daughter cards) demo board.

- High-density USB-PD adaptor developed with Industrial Technology Research Institute (ITRI) of Taiwan

Original – Cambridge GaN Devices

-

GaN / LATEST NEWS / PRODUCT & TECHNOLOGY / WBG2 Min Read

Infineon Technologies AG announced the launch of a new family of high-voltage discretes, the CoolGaN™ Transistors 650 V G5, further strengthening its Gallium Nitride (GaN) portfolio. Target applications for this new product family range from consumer and industrial switched-mode power supply (SMPS) such as USB-C adapters and chargers, lighting, TV, data center and telecom rectifiers to renewable energy and motor drives in home appliances.

The latest CoolGaN generation is designed as a drop-in replacement for the CoolGaN Transistors 600 V G1, enabling rapid redesign of existing platforms. The new devices provide improved figures of merit to ensure competitive switching performance in focus applications.

Compared to key competitors and previous product families from Infineon, the CoolGaN Transistors 650 V G5 offer up to 50 percent lower energy stored in the output capacitance (E oss), up to 60 percent improved drain-source charge (Q oss) and up to 60 percent lower gate charge (Q g). Combined, these features result in excellent efficiencies in both hard- and soft-switching applications. This leads to a significant reduction in power loss compared to traditional silicon technology, ranging from 20 to 60 percent depending on the specific use case.

These benefits allow the devices to operate at high frequencies with minimal power loss, resulting in superior power density. The CoolGaN Transitors 650 V G5 enable SMPS applications to be smaller and lighter or to increase the output power range in a given form factor.

The new high-voltage transistor product family offers a wide range of R DS(on) package combinations. Ten R DS(on) classes are available in various SMD packages, such as ThinPAK 5×6, DFN 8×8 , TOLL and TOLT. All products are manufactured on high-performance 8-inch production lines in Villach (Austria) and Kulim (Malaysia). In the future, CoolGaN will transition to 12-inch production. This will enable Infineon to further expand its CoolGaN capacity and ensure a robust supply chain in the GaN power market, which is expected to reach $2 billion by 2029, according to Yole Group.

A demo featuring the CoolGaN Transistors 650 V G5 will be showcased at electronica 2024 in Munich from November 12 to 15 (hall C3, booth 502).

Original – Infineon Technologies

-

GaN / LATEST NEWS / PRODUCT & TECHNOLOGY / WBG2 Min Read

Power Integrations introduced a new member of its InnoMux™-2 family of single-stage, independently regulated multi-output offline power supply ICs. The new device features the industry’s first 1700 V gallium nitride switch, fabricated using the company’s proprietary PowiGaN™ technology.

The 1700 V rating further advances the state-of-the-art for GaN power devices, previously set by Power Integrations’ own 900 V and 1250 V devices, both launched in 2023. The 1700 V InnoMux-2 IC easily supports 1000 VDC nominal input voltage in a flyback configuration and achieves over 90 percent efficiency in applications requiring one, two or three supply voltages.

Each output is regulated within one percent accuracy, eliminating post regulators and further improving system efficiency by approximately ten percent. The new device replaces expensive silicon carbide (SiC) transistors in power supply applications such as automotive chargers, solar inverters, three-phase meters and a wide variety of industrial power systems.

Radu Barsan, vice president of technology at Power Integrations, said, “Our rapid pace of GaN development has delivered three world-first voltage ratings in a span of less than two years: 900 V, 1250 V and now 1700 V. Our new InnoMux-2 ICs combine 1700 V GaN and three other recent innovations: independent, accurate, multi-output regulation; FluxLink™, our secondary-side regulation (SSR) digital isolation communications technology; and zero voltage switching (ZVS) without an active-clamp, which all but eliminates switching losses.”

Original – Power Integrations

-

FINANCIAL RESULTS / LATEST NEWS2 Min Read

Magnachip Semiconductor Corporation announced financial results for the third quarter 2024.

YJ Kim, Magnachip’s CEO, commented, “Our Q3 revenue was at the high-end of guidance driven by broad-based growth in our Standard Product businesses, which is comprised of our MSS and PAS businesses. Standard Product revenue increased 25.9% sequentially and 24% year-over-year. Our discrete Power business benefited from leaner inventory in distribution channels as well as new product designs wins resulting in better-than-seasonal growth. In MSS, the strong sequential growth was due to increased demand for products targeted for China smartphone OEMs, automotive displays, and OLED IT.”

YJ Kim added, “Looking ahead, we expect our Standard Product business revenue in Q4 will modestly decline sequentially, which is better than typical seasonality experienced in past years. We reiterate our full-year guidance for double-digit growth in both MSS and PAS businesses in 2024.”

Financial Highlights

- Q3 consolidated revenue was $66.5 million, at the high-end of guidance range of $61.5-66.5 million.

- Q3 standard product business revenue was up 25.9% sequentially.

- Q3 consolidated gross profit margin of 23.3% was in-line with the mid-point of guidance range of 22.5-24.5%.

- Q3 standard product business gross profit margin was 24.4%, up 1.3 percentage points sequentially.

- Ended Q3 with cash of $121.1 million; and an additional non-redeemable short-term financial investment of $30 million.

- Repurchased approximately 0.5 million shares for aggregate purchase price of $2.5 million during the quarter.

Operational Highlights

- Broad-based sequential revenue growth in our PAS business was driven by leaner distribution channels and better-than-typical seasonality. Relative strength was more evident in industrial, computing, and consumer applications. Automotive continues to show strength with additional design wins in Japan and China.

- Started initial DDIC production and shipments for a premium smartphone model from a leading China OEM.

- Received a purchase order from a second leading China smartphone OEM and commenced shipments in October 2024.

- Began sampling our new OLED driver designed with next-generation IP, including sub-pixel rendering (SPR), refined color enhancement, color filter, brightness uniformity control and more than 20% reduction in power consumption than previous generation.

- Power IC revenue increased sequentially, driven primarily by demand for LCD TVs and OLED IT in tablets and notebooks.

Original – Magnachip Semiconductor

- Q3 consolidated revenue was $66.5 million, at the high-end of guidance range of $61.5-66.5 million.

-

STMicroelectronics N.V. (“ST”) reported U.S. GAAP financial results for the third quarter ended September 28, 2024. ST reported third quarter net revenues of $3.25 billion, gross margin of 37.8%, operating margin of 11.7%, and net income of $351 million or $0.37 diluted earnings per share. Jean-Marc Chery, ST President & CEO, commented:

- “Q3 net revenues were in line with the midpoint of our business outlook range. Our revenues, compared to our expectations, were higher in Personal Electronics, declined less in Industrial and were lower in Automotive. Q3 gross margin of 37.8% was broadly in line with the mid-point of our business outlook range.”

- “First nine months net revenues decreased 23.5% year-over-year across all reportable segments, particularly in Microcontrollers, which is impacted by a continuing weakness in the Industrial market. Operating margin was 13.1% and net income was $1.22 billion.”

- “Our fourth quarter business outlook, at the mid-point, is for net revenues of $3.32 billion, decreasing yearover-year by 22.4% and increasing sequentially by 2.2%; gross margin is expected to be about 38%, impacted by about 400 basis points of unused capacity charges.”

- “The midpoint of this outlook translates into full year 2024 revenues of about $13.27 billion, representing a 23.2% year-over-year decrease, in the low-end of the range indicated in the previous quarter, and a gross margin slightly below that provided in such indication.”

- “Based on our current customer order backlog and demand visibility, we anticipate a revenue decline between Q4 2024 and Q1 2025 well above normal seasonality.”

- “We are launching a new company-wide program to reshape our manufacturing footprint accelerating our wafer fab capacity to 300mm Silicon (Agrate and Crolles) and 200mm Silicon Carbide (Catania) and resizing our global cost base. This program should result in strengthening our capability to grow our revenues with an improved operating efficiency resulting in annual cost savings in the high triple-digit million-dollar range exiting 2027.”

Original – STMicroelectronics

-

Renesas Electronics Corporation announced consolidated financial results in accordance with IFRS for the nine months ended September 30, 2024.

Summary of Consolidated Financial Results (Note 1)

Summary of Consolidated Financial Results (Non-GAAP basis) (Note 2)

Three months ended September 30, 2024 Nine months ended September 30, 2024 Billion Yen % of Revenue Billion Yen % of Revenue Revenue 345.3 100.0 1,055.9 100.0 Gross profit 192.8 55.9 595.7 56.4 Operating profit 98.4 28.5 322.5 30.5 Profit attributable to owners of parent 86.0 24.9 288.5 27.3 EBITDA (Note 3) 121.4 35.2 388.0 36.7 Summary of Consolidated Financial Results (IFRS basis)

Three months ended September 30, 2024 Nine months ended September 30, 2024 Billion yen % of Revenue Billion yen % of Revenue Revenue 345.3 100.0 1,055.9 100.0 Gross profit 192.2 55.7 590.6 55.9 Operating profit 57.2 16.6 204.8 19.4 Profit attributable to owners of parent 60.6 17.6 200.3 19.0 EBITDA (Note 3) 109.0 31.6 355.3 33.7 Reconciliation of Non-GAAP gross profit to IFRS gross profit and Non-GAAP operating profit to IFRS operating profit

(Billion yen)

Three months ended September 30, 2024 Nine months ended September 30, 2024 Non-GAAP gross profit

Non-GAAP gross margin192.8

55.9%595.7

56.4%Amortization of purchased intangible assets and depreciation of property, plant and equipment (0.2) (0.8) Stock-based compensation (0.8) (2.1) Other reconciliation items in non-recurring

expenses and adjustments (Note 4)0.4 (2.4) IFRS gross profit

IFRS gross margin192.2

55.7%590.6

55.9%Non-GAAP operating profit

Non-GAAP operating margin98.4

28.5%322.5

30.5%Amortization of purchased intangible assets and depreciation of property, plant and equipment (28.7) (85.0) Stock-based compensation (10.0) (24.9) Other reconciliation items in non-recurring expenses and adjustments (Note 4) (2.4) (7.8) IFRS operating profit

IFRS operating margin57.2

16.6%204.8

19.4%Note 1: All figures are rounded to the nearest 100 million yen.

Note 2: Non-GAAP figures are calculated by removing or adjusting non-recurring items and other adjustments from GAAP (IFRS) figures following a certain set of rules. The Group believes non-GAAP measures provide useful information in understanding and evaluating the Group’s constant business results.

Note 3: Operating profit + Depreciation and amortization.

Note 4: “Other reconciliation items in non-recurring expenses and adjustments” includes the non-recurring items related to acquisitions and other adjustments as well as non-recurring profits or losses the Group believes to be applicable.

Original – Renesas Electronics

-

FINANCIAL RESULTS / LATEST NEWS1 Min Read

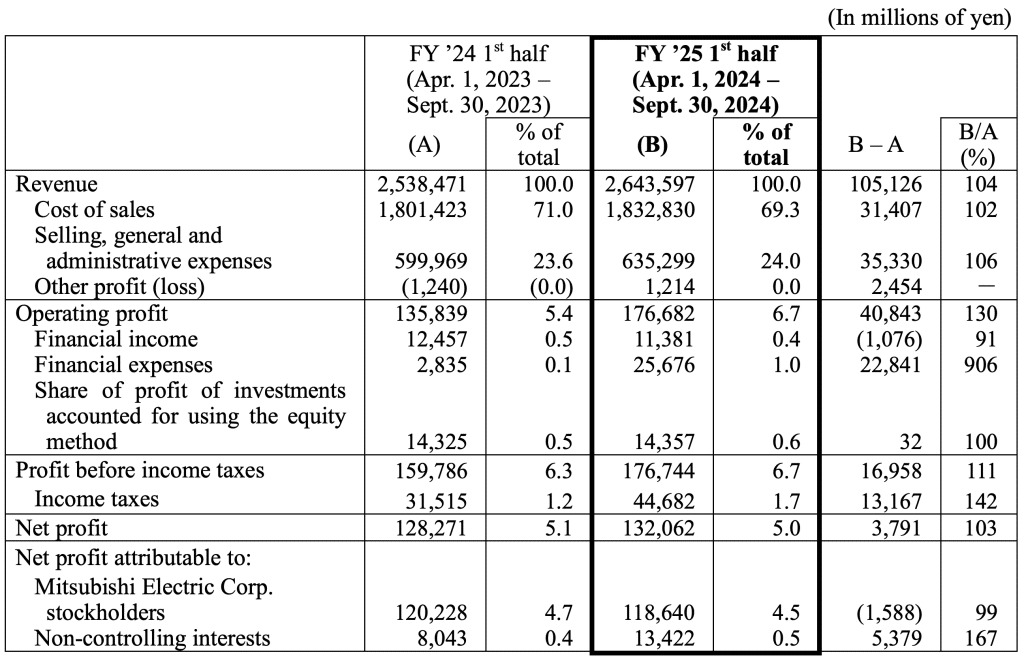

Mitsubishi Electric Corporation announced its consolidated financial results for the second quarter (first half), ended September 30, 2024, of the current fiscal year ending March 31, 2025 (fiscal 2025).

Original – Mitsubishi Electric