-

GaN / LATEST NEWS / PRODUCT & TECHNOLOGY / WBG3 Min Read

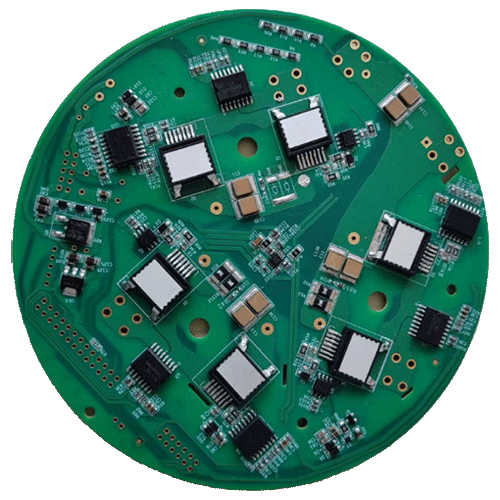

Cambridge GaN Devices is partnering with Qorvo® to develop a reference design and evaluation kit (EVK) that showcases GaN for motor control applications. CGD aims to speed the use of GaN power ICs in BLDC and PMSM applications, resulting in higher power, highly efficient, compact and reliable systems. Qorvo is building an EVK for its PAC5556A motor/control IC that is powered by CGD’s ICeGaN™ (IC-enhanced GaN) technology.

GIORGIA LONGOBARDI | CEO, CGD

“Because ICeGaN – unlike other GaN implementations from other companies – integrates the interface circuitry but not the controller together with the GaN HEMT, it is simple to combine with highly integrated motor controller and drive ICs such as Qorvo’s PAC5556A 600 V High Performance BLDC / PMSM Motor Controller and Driver. We are delighted to partner with Qorvo to enable motor controller and driver applications to enjoy the benefits of GaN power.”JEFF STRANG | GENERAL MANAGER, POWER MANAGEMENT BUSINESS UNIT, QORVO

“Wide bandgap semiconductors such as GaN and SiC are being actively considered in various motor control applications for the power density and efficiency benefits they bring. CGD’s ICeGaN technology offers ease of use and reliability, two crucial factors for motor control and drive designers. We are excited to see the reaction of design engineers when they experience the power of GaN combined with our highly integrated PAC5556A 600V BLDC motor control solution.”GaN brings a variety of benefits, primarily lower losses, which results in higher efficiency, leading to increased power availability and less heat. This reduces the need for complex, bulky, and costly thermal management solutions, resulting in smaller, more powerful systems that have a longer life. GaN also delivers higher torque at low speeds and, therefore, more accurate control. Also, GaN allows high-speed switching, which can reduce audible noise, which is especially valued for domestic items such as ceiling fans, heat pumps, and refrigerators.

In addition to being easy to use, ICeGaN offers several other significant benefits over other GaN devices. The gate drive voltage of ICeGaN is compatible with IGBTs. Because ICeGaN integrates the Miller clamp within the GaN IC, a negative Turn-Off voltage is not required, and low-cost current drivers can be used. Finally, ICeGaN includes a useful current sense function, simplifying circuit design and reducing BOM.

The reference design is available today, and EVK RD5556GaN will be available for purchase in Q324. It will also be shown on CGD’s booth Hall 7 643 at the PCIM exhibition in Nuremberg, Germany, 11-13 June. Qorvo will also exhibit at PCIM, on booth Hall 7 406.

Original – Cambridge GaN Devices

-

GaN / LATEST NEWS / PRODUCT & TECHNOLOGY / WBG3 Min Read

Infineon Technologies AG announced two new CoolGaN™ product technologies, CoolGaN bidirectional switch (BDS) and CoolGaN Smart Sense. CoolGaN BDS provides exceptional soft- and hard-switching behavior, with bidirectional switches available at 40 V, 650 V and 850 V. Target Applications of this family include mobile device USB ports, battery management systems, inverters, and rectifiers.

The CoolGaN Smart Sense products feature lossless current sensing, simplifying design and further reducing power losses, as well as transistor switch functions integrated into one package. They are ideal for usage in consumer USB-C chargers and adapters.

The CoolGaN BDS high voltage will be available at 650 V and 850 V and feature a true normally-off monolithic bi-directional switch with four modes of operation. Based on the gate injection transistor (GIT) technology, the devices have two separate gates with substrate terminal and independent isolated control. They utilize the same drift region to block voltages in both directions with outstanding performance under repetitive short-circuit conditions.

Applications can benefit by using one BDS instead of four conventional transistors, resulting in higher efficiency, density, and reliability. Furthermore, significant cost savings are achieved. The devices optimize performance in the replacement of back-to-back switches in single-phase H4 PFC and HERIC inverters and three-phase Vienna rectifiers. Additional implementations include single-stage AC power conversion in AC/DC or DC/AC topologies.

The CoolGaN BDS 40 V is a normally-off, monolithic bi-directional switch based on Infineon’s in-house Schottky Gate GaN technology. It can block voltages in both directions, and through a single-gate and common-source design, it is optimized to replace back-to-back MOSFETs used as disconnect switches in battery-powered consumer products. The first 40 V CoolGaN BDS product has a 6 mΩ R DS(on), with a range of products to follow. Benefits of using 40 V GaN BDS vs. back-to-back Si FETs include 50 – 75 percent PCB area savings and a reduction of power losses by more than 50 percent, all at a lower cost.

The CoolGaN Smart Sense products feature 2 kV electrostatic discharge withstand and can connect to controller current sense for peak current control and overcurrent protection. The current sense response time is ~200 ns, which is equal or less than common controller blanking time for ultimate compatibility.

Implementing the devices results in increased efficiency and cost savings. At a higher R DSs(on) of e.g. 350 mΩ, the CoolGaN Smart Sense products offer similar efficiency and thermal performance at lower cost compared to traditional 150mΩ GaN transistors. Moreover, the devices are footprint compatible to Infineon’s transistor-only CoolGaN package, eliminating the need for layout rework and PCB respin, and further facilitating design with Infineon’s GaN devices.

Engineering samples of the CoolGaN BDS 40 V are available now for 6 mΩ and will follow in Q3 2024 for 4 mΩ and 9 mΩ. Samples of the CoolGaN BDS 650 V will be available in Q4 2024, and 850 V will follow early 2025. CoolGaN Smart Sense samples will be available in August 2024. Further information is available here: https://www.infineon.com/cms/en/product/promopages/GaN-innovations/

Original – Infineon Technologies