-

LATEST NEWS / SiC / WBG2 Min Read

SemiQ Inc has begun shipping its SiC MOSFET modules for integration into advanced cell cycling systems used by several of the world’s leading battery manufacturers.

In lithium-ion batteries, cell cyclers enable the formation of a stable solid electrolyte interphase to enable increased longevity and performance. The systems also enable battery manufacturers to perform battery degradation analysis, temperature and stress testing, and check for defects or performance issues.

To undertake these tasks, the cyclers need to accurately charge and discharge batteries, with high switching frequencies enabling more precise control of current and voltage to avoid damage from overcharging/discharging. For this function, the MOSFETs need to withstand the thermal stress of repeated power cycling, with failure leading to test disruption and inaccurate data. Conversion efficiency is also vital in minimizing operational costs.

SemiQ is supplying its GCMX003A120S3B1-N and the GCMX003A120S7B1 QSiC™ 1200 V SiC half-bridge modules for use in 100 kW cyclers (10 x 10 kW cells with parallel connections).

These high-speed switching MOSFET modules are highly efficient with exceptionally low switching losses, are designed with a reliable body diode, have been tested to over 1350 V and implement a rugged design with easy mounting. Each 10 kW cell will integrate 12 modules, with 120 per 100 kW per cycler.

Dr. Timothy Han, President at SemiQ said: “Reports show that the electrification of transportation is among the most important steps that can be taken to reach net-zero. For this, the evaluation of battery performance, durability, and efficiency plays a vital role in enabling the development of longer-range, longer-life EV batteries. We’re delighted to be working with one of the world’s leading cell cyclers and this partnership is testament to the ruggedness and efficiency of our SiC technology.”

Datasheets for the GCMX003A120S3B1-N and GCMX003A120S7B1 modules can be downloaded via the product page, here.

Original – SemiQ

-

GaN / LATEST NEWS / SiC / WBG3 Min Read

Navitas Semiconductor has announced that its portfolio of 3.2kW, 4.5kW, and 8.5 kW AI data center power supply unit (PSU) designs exceed the new 80 PLUS ‘Ruby’ certification, focused on the highest level of efficiency for redundant server data center PSUs.

The 80 PLUS certification program assesses and certifies the energy efficiency of internal PSUs in computers and servers. The ‘Ruby’ certification was announced in January 2025 by 80 PLUS’s administrating body, CLEAResult, following its endorsement by the Green Grid consortium.

‘Ruby’ is the most rigorous PSU efficiency standard since the ‘Titanium’ certification was released 14 years ago. In comparison, Ruby sets an additional 1% system efficiency across all load conditions, except at 50% load (which requires a 0.5% increase), to achieve a new benchmark of 96.5% efficiency.

This new standard offers the industry a clear path to enhanced energy efficiency, helping data centers address the evolving needs of cloud storage, commercial sectors, and the increasing pressure on the grid from AI computing. For example, every Ruby-certified 3.2 kW CRPS185 PSU can save up to 420 kilowatt-hours during a 3-year lifetime. That is the equivalent of over 400 kg of CO2 emissions.

Navitas exceeds both Ruby and Titanium certifications on their portfolio of AI data center PSU reference designs, ranging from 3.2 kW to 8.5 kW, and are powered by high-power GaNSafe™ ICs and GeneSiC™ Gen 3 ‘Fast’ SiC MOSFETs.

Navitas is the established leader in AI data center solutions enabled by GaN and SiC technology. In August 2023, they introduced a high-speed, high-efficiency 3.2 kW CRPS, achieving a 40% smaller size than best-in-class, legacy silicon solutions for power-hungry AI and Edge computing. This was followed by the world’s highest power density 4.5 kW CRPS, achieving a ground-breaking 137 W/in3, and efficiency of over 97%.

In November 2024, Navitas released the world’s first 8.5 kW AI data center power supply powered by GaN and SiC that could meet 98% efficiency, complying with the Open Compute Project (OCP) and Open Rack v3 (ORv3) specifications. Additionally, Navitas created IntelliWeave, an innovative patented new digital control technique, that when combined with high-power GaNSafe and Gen 3-Fast SiC MOSFETs, enables PFC peak efficiencies to 99.3% and reduces power losses by 30% reduction compared to existing solutions.

“Compared with Titanium, Ruby cuts the allowable PSU losses significantly and will be critical in enabling the data center industry to reduce its carbon footprint and cut operational costs,” said Gene Sheridan, CEO and co-founder of Navitas. “With the industry set to consume 1,000 TWh annually by next year1, every percentage point improvement in efficiency represents a reduction of 10 TWh, or approximately 3.5 million tons of CO22. Advances in our GaNFast and GeneSiC products enable these targets to be met and significantly exceeded.”

Navitas’ AI Power Roadmap and 80 PLUS Ruby-compliant demos can be viewed at the ‘Planet Navitas’ booth #1107 during the APEC 2025 conference, which takes place at Atlanta’s Georgia World Congress Center from March 16 to 20.

Original – Navitas Semiconductor

-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / WBG2 Min Read

Many industrial applications today are moving towards higher power levels with minimized power losses. One way to achieve this is to increase the DC link voltage. Infineon Technologies AG is addressing this market trend with the CoolSiC™ Schottky diode 2000 V G5 product family, the first discrete silicon carbide diodes with a breakdown voltage of 2000 V, introduced in September 2024.

The product portfolio has now been expanded to include a Schottky diode in the TO-247-2 package, which is pin-compatible with most existing TO-247-2 packages. The product family fits perfectly for applications with DC link voltages up to 1500 V DC, making it ideal for solar and EV chargers.

The CoolSiC Schottky diode 2000 V G5 in the TO-247-2 package is available with current ratings ranging from 10 to 80 A. It allows developers to achieve higher power levels in their applications while reducing the component count by half compared to 1200 V solutions. This simplifies the overall design and facilitates a seamless transition from multi-level to two-level topologies.

In addition, the Schottky diode in the TO-247-2 package incorporates .XT interconnection technology, which significantly reduces thermal resistance and impedance, thereby enhancing heat management. Humidity robustness has been validated through HV-H3TRB reliability testing. The diodes exhibit neither reverse recovery nor forward recovery, and feature a low forward voltage, ensuring improved system performance.

The 2000 V diode family is a perfect match for the CoolSiC MOSFETs 2000 V in the TO-247Plus-4 HCC package that Infineon launched in the spring of 2024. In addition to the TO-247-2 package, the CoolSiC Schottky Diode 2000 V is also available in the TO-247PLUS-4 HCC package.

Original – Infineon Technologies

-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / WBG4 Min Read

NoMIS Power has announced a major breakthrough in improving the short-circuit withstand time (SCWT) of SiC MOSFETs. This innovation addresses one of the key challenges limiting the widespread adoption of SiC technology in high-power applications.

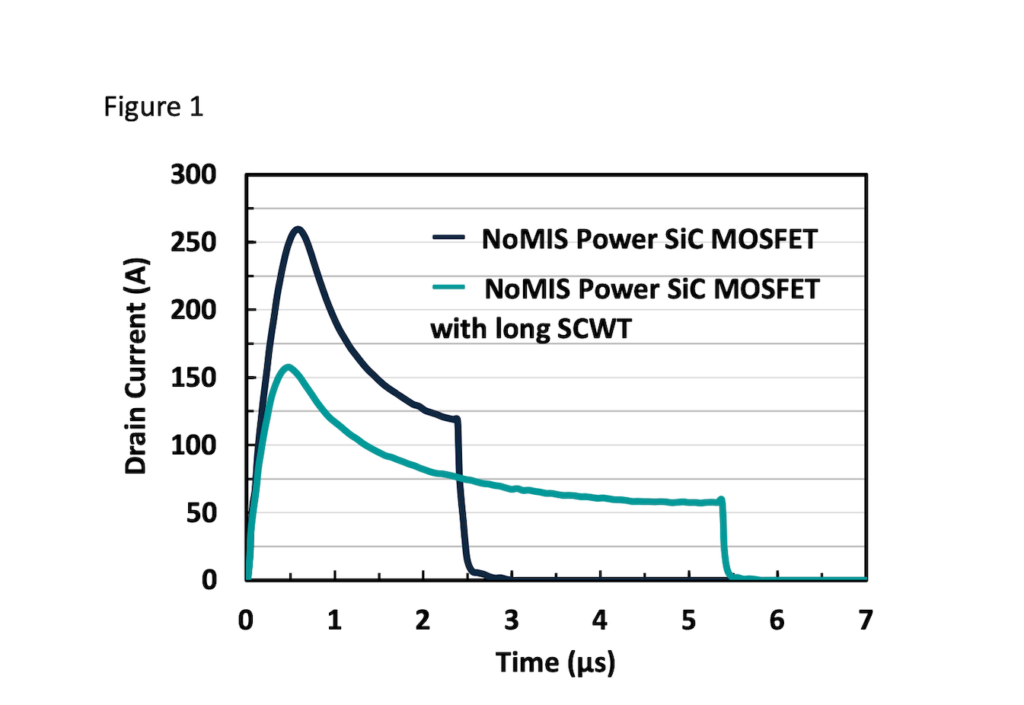

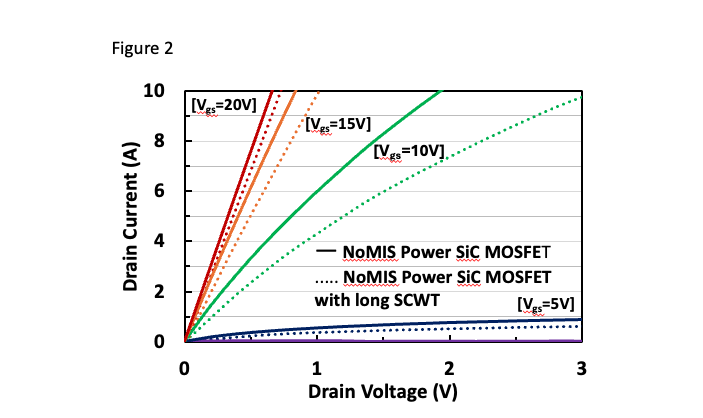

Silicon carbide (SiC) devices have gained prominence in power electronics due to their high efficiency, fast switching, and superior thermal performance. However, their historically lower short-circuit robustness compared to silicon-based IGBTs has posed challenges for their use in high-voltage and high-reliability environments, such as industrial drives, electric vehicles, and grid applications. NoMIS Power’s latest advancement significantly extends the SCWT of SiC MOSFETs to a minimum of 5 µs (Fig. 1), compared to the current industry standard of 2-3 µs, with no deleterious effect on specific on-resistance (Ron,sp) (Fig. 2). This enhancement greatly improves reliability and unlocks new opportunities for system designers seeking to maximize performance while maintaining fault tolerance.

Figure 1: Drain currents of the NoMIS Power SiC MOSFET and NoMIS Power SiC MOSFET with long SCWT under short-circuit conditions right before failure. Drain currents of the 1.2 kV, 80 mΩ SiC MOSFET (dark blue) and the long SCWT 1.2 kV, 80 mΩ SiC MOSFET (light blue) from NoMIS Power are compared. The measurement for short-circuit was conducted under the following conditions: Rg of 20 Ω, Vgs of 20 V, and a Vds of 800 V.

By tuning the trade-off between Ron,sp and SCWT using NoMIS Power’s proprietary SiC MOSFET fabrication design and process flow, the performance shown in Fig. 1 & Fig. 2 was achieved; and can be similarly managed depending on the specific application. Complete optimization of SiC MOSFETs with long SCWT using this approach will allow NoMIS Power to further extend the SCWT while maintaining negligible impact on Ron,sp.

Figure 2: Typical output characteristics of NoMIS Power 1.2 kV, 80 mQ SiC MOSFET and NoMIS Power 1.2 kV, 80 mQ SiC MOSFET with long SCWT showing no significant negative impact on on-resistance.

“At NoMIS Power, we have focused extensively on device architecture engineering, leading to a significant advancement in SiC short-circuit withstand time,” said Woongje Sung, CTO at NoMIS Power. “We believe this achievement provides valuable advantages to the power electronics community, helping engineers integrate SiC solutions with greater confidence in applications where robustness is critical.”

NoMIS Power’s long SCWT devices are well-screened for latent defects and offer easier gate driver desaturation (dSat) design for high di/dt and dv/dt, enabling faster switching frequencies of up to hundreds of kHz. Initial test results demonstrate a 2X to 4X increase in short-circuit withstand time compared to existing SiC devices, positioning NoMIS Power’s technology as a frontrunner in the next generation of power semiconductors. Additionally, when coupled with packaging innovations that impact junction-to-case thermal capacitance, alongside novel thermal management techniques with high heat transfer coefficients, the overall SCWT of the SiC MOSFET can be further improved.

The impact of this innovation extends across multiple industries, including renewable energy, electric transportation, and high-power industrial applications. A longer short-circuit withstand time ensures rugged and reliable performance in critical applications, reinforcing the robustness of SiC-based power systems. For example, built-in redundancy of the SiC MOSFETs inside power converters, which impacts costs as well as power density, can be reduced. Furthermore, applications sensitive to electromagnetic inference, that cannot solely rely on digital control and sensing schemes to detect and act upon short-circuit events, will now be able to effectively utilize SiC MOSFETs with lower risk. As SiC adoption accelerates, NoMIS Power’s breakthrough will play a pivotal role in enhancing the reliability and safety of SiC-based power converters and systems.

NoMIS Power is showcasing this breakthrough technology at APEC 2025, March 16-20, Atlanta, GA, Booth 548 along with its expanded range of SiC discretes and power modules.

Original – NoMIS Power

-

LATEST NEWS / SiC / WBG2 Min Read

SemiQ Inc will give the first official unveiling of the company’s new 1700 V and 1200 V Gen 3 SiC MOSFETs at the 2025 Applied Power Electronics Conference (APEC).

APEC takes place at the Georgia World Congress Center in Atlanta from March 16, with SemiQ’s booth located at stand #1348.

SemiQ’s 1200 V Gen3 SiC was announced in February, delivering an improved performance with a smaller die size and at a lower cost. The series includes automotive qualified (AEC-Q101) options and Known Good Die (KGD) testing has been implemented across the series with verification at voltages exceeding 1400 V, plus avalanche testing to 800 mJ. Reliability is further improved through 100% gate-oxide burn-in screening and UIL testing of discrete packaged devices.

The company’s new 1700 V MOSFET family of MOSFETS and modules with AEC-Q101 certification is designed to meet the needs of medium-voltage high power conversion applications, from photovoltaic, wind inverters and energy storage to EV and roadside charging as well as uninterruptable power supplies, and induction heating/welding. These switching planar D-MOSFETs enable more compact system designs with higher power densities and have been tested to KGD beyond 1900 V, with UIL avalanche testing to 600 mJ.

Dr. Timothy Han, President at SemiQ said: “There is so much innovation happening in power electronics right now and we’re delighted to have launched our next generation technologies in time to have them on display at APEC. The show brings together many of the leading minds within the industry and we’re looking forward to discussing the challenges faced and how we can help them.”

Original – SemiQ

-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / WBG2 Min Read

SemiQ Inc has announced a family of three 1200V SiC full-bridge modules, each integrating two of the company’s rugged high-speed switching SiC MOSFETs with reliable body diode. The modules have been developed to simplify the development of photovoltaic inverters, energy storage, battery charging and other high-frequency DC applications.

Available in 18, 38 and 77mΩ (RDSon) variants, the modules have been tested at voltages exceeding 1350V and deliver a continuous drain current of up to 102A, a pulsed drain current of up to 250A and a power dissipation of up to 333W.

Operational with a junction temperature of up to 175oC, the rugged B2 modules have exceptionally low switching losses (EON 0.13mJ, EOFF 0.04mJ at 25oC – 77mΩ module), low zero-gate voltage drain/gate source leakage (0.1µA/1nA – all modules) and low junction to case thermal resistance (0.4oC per watt – 18mΩ module).

“By integrating high-speed SiC MOSFETs with exceptional performance and reliability, our new QSiC 1200V family of full-bridge modules sets a new standard for power density and efficiency in demanding DC applications. This family of modules simplifies system design, and enables faster time-to-market for next-generation solar, storage, and charging solutions,” said Seok Joo Jang, Director of Module Engineering at SemiQ.

Available immediately, the modules can be mounted directly to a heat sink, are housed in a 62.8 x 33.8 x 15.0mm package (including mounting plates) with press fit terminal connections and split DC negative terminals.

Original – SemiQ