-

LATEST NEWS / PROJECTS / TOP STORIES3 Min Read

June 12 marked a milestone in the history of Siltronic AG: after more than 500 construction days and roughly 23 million working hours, Siltronic inaugurated one of the world’s most advanced wafer fabs. The inauguration of the new production facility, which is one of the most modern and cost-efficient of its kind, took place in Singapore.

The highly automated fab at JTC’s Tampines Wafer Fab Park was officially opened in the presence of around 150 guests, including numerous high-ranking representatives of the Singaporean government, customers and suppliers. Singapore’s Deputy Prime Minister Heng Swee Keat was the Guest of Honour to grace the occasion. The fab was commissioned at the beginning of 2024 and will now be ramped to full capacity over several years.

“With our new fab, we will accompany the future growth of the wafer industry for many years to come and take Siltronic to a new level. What the entire team, including all business partners, has achieved is a masterpiece, and I would like to thank everyone for their outstanding contribution,” said Dr. Michael Heckmeier, CEO of Siltronic AG, in his speech.

Ms. Jacqueline Poh, Managing Director of Singapore Economic Board (EDB) said: “We are proud of our long-standing partnership with Siltronic. As one of top 5 global wafer suppliers, Siltronic’s new fab is a significant expansion that not only supplies to Singapore’s semiconductor industry but also strengthens the resilience of the global semiconductor supply chain. This investment will create good jobs and further grow the existing collaboration that Siltronic has with local suppliers in automation and precision components.”

The success story of Siltronic in Singapore began in 1997 with the founding of Siltronic Singapore Pte. Ltd. in JTC’s Tampines Wafer Fab Park. The first 200 mm wafers were produced as early as 1999. This was followed in 2006 by the establishment of a joint venture with Samsung and the start of construction of the first 300 mm fab, from which the first wafers were delivered to customers in 2008. The foundation stone for the second 300 mm fab was laid in 2021, and it was officially opened today. Singapore is Siltronic’s largest production site.

Today’s inauguration of the state-of-the-art wafer fab in Singapore is not only the largest investment in Siltronic’s history, but also a milestone of which Siltronic is extremely proud. With its high level of automation and impressive efficiency, the fab sets new standards in our industry and strengthens Siltronic’s position as one of the world’s leading wafer manufacturers.

Original – Siltronic

-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / TOP STORIES / WBG2 Min Read

WeEn Semiconductors unveiled new families of silicon carbide (SiC) MOSFETs and Schottky Barrier Diodes (SBDs) in TSPAK packaging at this year’s PCIM Europe exhibition and conference. The company has also used the event to showcase for the first time a comprehensive range of integrated SiC power modules in Nuremberg, from June 11-13, 2024.

WeEn Semiconductor’s new TSPAK MOSFET and SBD devices address the demand for high-performance, compact and reliable power management in applications ranging from automotive charging and on-board charger applications to photovoltaic (PV) inverters and high-power-density power supplies (PSUs).

Offering a variety of configuration options for maximum design flexibility, the company’s new SiC modules are ideal for applications such as EV charging, energy storage systems, PV inverters, motor drives, industrial PSUs and test instrumentation.

Originally developed for automotive applications, TSPAK devices combine innovative top-side cooling capability with low thermal impedance to deliver enhanced thermal performance. By removing the PCB thermal resistance from the thermal dissipating path, the Junction-Ambient thermal resistance improves by 16-19%.

This supports high reliability by enabling a greater number of power cycles than conventional packaging as well as providing the increased power densities demanded by compact system designs. Low circuit inductance and low EMC noise help to improve performance and reduce filtering requirements. The WeEn Semiconductors family of TSPAK MOSFETs features 650V, 750V, and 1200V options with resistances ranging from 12mΩ to 150mΩ. TSPAK SBDs are available with current ratings of 10 to 40A in 650V, 750V, and 1200V variants.

Visitors to WeEn’s stand in Hall 9, booth 538, will have the first opportunity to explore the company’s extensive range of SiC power modules. With a wide range of topology options, including half-bridge, four-pack, six-pack, and MPPT booster configurations, the power modules support voltages ranging from 650V to 1200V. Depending on the option chosen and special designs, modules incorporate a variety of advanced features including synchronized chip current sharing, integrated temperature sensors, topside cooling structures and the latest clip-bond technologies.

Original – WeEn Semiconductors

-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / TOP STORIES / WBG2 Min Read

Qorvo® announced the industry’s first 4 milliohm silicon carbide (SiC) junction field effect transistor (JFET) in a TOLL package. It was designed for circuit protection applications including solid-state circuit breakers, where low resistance, superior thermal performance, small size and reliability are paramount.

With RDS(on) of just 4 milliohm, the UJ4N075004L8S offers the industry’s lowest on-resistance among the 650V to 750V class of power devices in standard discrete packages. This low RDS(on) drives significant reductions in heat generation and, when coupled with a compact TOLL package, enables a solution size that is 40% smaller than competing devices in TO-263 packages.

This small solution size supports the space-limited dimensions of today’s electromechanical circuit breakers and operates without the need for elaborate cooling systems, accelerating the transition from electromechanical circuit breakers to semiconductor-based solid-state circuit breakers (SSCBs).

“With the introduction of the UJ4N075004L8S, Qorvo continues to lead the way in SiC power innovation, catalyzing the emergence of applications such as circuit protection with ultra-low RDS(on) FET offerings in very small footprints,” said Ramanan Natarajan, director of product line marketing for Qorvo’s SiC Power Products business. “The SSCB market is growing rapidly, and Qorvo’s newest product marks a significant milestone in the evolution of the technology.”

Qorvo’s JFETs are highly robust devices well suited to meet the challenges of circuit protection, providing the ability to turn off at very high inrush currents during circuit faults. Qorvo’s newest JFET can also withstand high instantaneous junction temperatures without experiencing degradation or parametric drift. The normally-on nature of the JFET lends itself to seamless integration into systems where the switch is in the on-state by default and in turn-off state under fault conditions.

The UJ4N075004L8S is now available for sampling and will enter full production in Q4 2024, accompanied by additional JFET options, including 750V with 5 milliohm and 1200V with 8 milliohm ratings, all in TO-247 packaging. For more details about this transformative power technology and detailed product specifications, please visit UJ4N075004L8S.

Original – Qorvo

-

GaN / LATEST NEWS / PRODUCT & TECHNOLOGY / TOP STORIES / WBG3 Min Read

Texas Instruments introduced the industry’s first 650V three-phase GaN IPM for 250W motor drive applications. The new GaN IPM addresses many of the design and performance compromises engineers typically face when designing major home appliances and heating, ventilation and air-conditioning (HVAC) systems.

The DRV7308 GaN IPM enables more than 99% inverter efficiency, optimized acoustic performance, reduced solution size and lower system costs. It is on display at the Power Electronics, Intelligent Motion, Renewable Energy and Energy Management (PCIM) Conference, held June 11-13 in Nuremberg, Germany.

“Designers of high-voltage home appliances and HVAC systems are striving to meet higher energy-efficiency standards to support environmental sustainability goals around the world,” said Nicole Navinsky, Motor Drives business unit manager at TI. “They are also addressing consumer demand for systems that are reliable, quiet and compact. With TI’s new GaN IPM, engineers can design motor driver systems that deliver all of these expectations and operates at peak efficiency.”

Improve system efficiency and reliability with TI GaN

Worldwide efficiency standards for appliances and HVAC systems such as SEER, MEPS, Energy Star and Top Runner are becoming increasingly stringent. The DRV7308 helps engineers meet these standards, leveraging GaN technology to deliver more than 99% efficiency and improve thermal performance, with 50% reduced power losses compared to existing solutions.

In addition, the DRV7308 achieves industry-low dead time and low propagation delay, both less than 200ns, enabling higher pulse-width modulation (PWM) switching frequencies that reduce audible noise and system vibration. These advantages plus the higher power efficiency and integrated features of the DRV7308 also reduce motor heating, which can improve reliability and extend the lifetime of the system.

To learn more about the benefits of GaN technology, read the white paper, “How three-phase integrated GaN technology maximizes motor-drive performance.”

Advanced integration and high power density reduce solution size and costs

Supporting the trend of more compact home appliances, the DRV7308 helps engineers develop smaller motor drive systems. Enabled by GaN technology, the new IPM delivers high power density in a 12mm-by-12mm package, making it the industry’s smallest IPM for 150W to 250W motor-drive applications.

Because of its high efficiency, the DRV7308 eliminates the need for an external heatsink, resulting in motor drive inverter printed circuit board (PCB) size reduction of up to 55% compared to competing IPM solutions. The integration of a current sense amplifier, protection features and inverter stage further reduces solution size and cost.

To learn about designing more efficient, compact motor systems, see the GaN IPM page on TI.com.

This high-efficiency, high-voltage GaN IPM is the latest example of TI innovations to help solve engineering challenges and transform motor designs.

TI’s reliable high-voltage technology at PCIM 2024

Visitors to PCIM can see new products and solutions from TI that are enabling the transition to a more sustainable future with reliable high-voltage technology in Hall 7, Booth 652. In addition to the DRV7308 GaN IPM, TI highlights at PCIM include:

- Next-generation electric vehicle (EV) propulsion system: TI is demonstrating a new 800V, 750kW SiC-based scalable traction inverter system for EV six-phase motors, in collaboration with EMPEL Systems. The demonstration features high power density and efficiency using TI’s high-performance isolated gate drivers, isolated DC/DC power modules and Arm® Cortex®-R MCUs.

- TI’s manager of high-voltage power systems applications, Sheng-Yang Yu, will speak on June 11 in the Markt & Technik panel discussion: “Will SiC ultimately Hold its Own against GaN?”

- TI’s manager of renewable energy systems, Harald Parzhuber, will speak on June 12 in Bodo’s Power Systems panel discussion: “GaN Wide Bandgap Design, the Future of Power.”

Original – Texas Instruments

-

LATEST NEWS / TOP STORIES3 Min Read

Infineon Technologies AG will provide customers with comprehensive Product Carbon Footprint (PCF) data, taking a pioneering role in the semiconductor industry. The company is committed to eventually providing PCF data for its entire product portfolio, starting now with about half of its portfolio.

The initiative will empower customers to advance their own sustainability goals and reduce their carbon footprint effectively along the entire supply chain. The Product Carbon Footprint is a metric that quantifies the greenhouse gas emissions associated with an individual product, allowing the comparison of different products’ climate impact. Infineon will share more insights with customers at the upcoming PCIM trade fair in Nuremberg, Germany, from 11 to 13 June 2024.

“By providing comprehensive Product Carbon Footprint data, we are driving the vision of a net-zero society and empowering our customers to reduce carbon emissions even more effectively,” says Elke Reichart, Member of the Management Board and Chief Digital and Sustainability Officer at Infineon. “Infineon is taking a leading role in carbon transparency by committing to include the entire product portfolio over the coming years. This underlines our ambition to be a leader not only in terms of technology, but also sustainability.”

The specific data Infineon provides on its individual products is essential for the growing number of customers who want to increase transparency on their own carbon footprint. Moreover, it supports informed decision making to leverage additional potential for reducing emissions along the value chain.

In the absence of established industry standards, Infineon has developed a robust methodology to calculate the Product Carbon Footprint, incorporating customer needs and best practices. Infineon includes emissions from raw materials and supplies, its own manufacturing processes, manufacturing partners and transportation to the customer (“from cradle to gate”).

This means that the Product Carbon Footprint reported by Infineon covers scope 1 and 2 emissions as well as scope 3 emissions from suppliers and manufacturing partners, all the way to the customer’s gate. The Product Carbon Footprint is expressed in kilograms of carbon dioxide equivalent (kg CO 2e).

Infineon has published the assessment of reference product families on the Infineon website.

Driving transparency goes hand in hand with Infineon’s strong commitment to decarbonization and digitalization. Infineon’s products make a major contribution to the global energy transition and thus to a net-zero society. They are used in solar and wind power plants, electric cars and increase energy efficiency in numerous applications, including AI data centers. Over their lifetime, the company’s chips overall save 34 times the amount of CO 2e emitted during their production.

Breaking the carbon footprint down to the product level is another major milestone in Infineon’s sustainability journey. Infineon has already pledged to achieve carbon neutrality by 2030 for direct and indirect emissions (scope 1 and 2). Last year, the company additionally committed to setting a science-based target encompassing supply chain emissions (scope 3) as well.

Original – Infineon Technologies

-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / TOP STORIES / WBG1 Min Read

Mitsubishi Electric Corporation has begun shipping low-current 3.3kV/400A and 3.3kV/200A versions of a Schottky barrier diode (SBD) embedded silicon carbide (SiC) metal-oxide-semiconductor field-effect transistor (MOSFET) module for large industrial equipment, including rolling stock and electric power systems, from today, June 10.

Together with the existing 3.3kV/800A version, the newly named UnifullTM series comprises three modules to meet the growing demand for inverters capable of increasing power output and power conversion efficiency in large industrial equipment. The new modules will be exhibited at major trade shows, including Power Conversion Intelligent Motion (PCIM) Europe 2024 in Nuremberg, Germany from June 11 to 13.

Mitsubishi Electric’s SBD-embedded SiC-MOSFET modules, including the 3.3kV/800A version released on March 29, feature an optimized package structure to reduce switching loss and improve SiC performance. Compared to existing power modules, UnifullTM modules, significantly reduce switching loss and contribute to higher power output and efficiency in large industrial equipment, making them suitable for auxiliary power supplies in railcars and drive systems with relatively small capacities.

Original – Mitsubishi Electric

-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / TOP STORIES / WBG3 Min Read

Vishay Intertechnology, Inc. announced that at PCIM Europe 2024 the company will be showcasing its broad portfolio of power management solutions that address several increasingly important trends in power electronics, including e-mobility, high efficiency power conversion, energy storage, and grid management. In Hall 9, Booth 208, Vishay experts will be available to discuss the company’s extensive offering of passive and semiconductor solutions for these next-generation applications.

Taking center stage for Vishay at PCIM will be the company’s newly released 1200 V MaxSiC™ series silicon carbide (SiC) MOSFETs, which deliver on-resistances of 55 mW, 95 mW, and 280 mΩ in standard packages for industrial applications, with custom products also available.

In addition, Vishay will provide a roadmap for 650 V to 1700 V SiC MOSFETs with on-resistances ranging from 10 mΩ to 1 Ω. Vishay’s SiC platform is based on proprietary MOSFET technology — enabled through the company’s acquisition of MaxPower Semiconductor, Inc. — which will address market demands in traction inverter, photovoltaic energy conversion and storage, on-board charger, and charging station applications. At the booth, Vishay’s experts will also be discussing upcoming planned releases of the MaxSiC platform, including AEC-Q101 Automotive Grade products.

At PCIM, Vishay will be offering a variety of application-focused demonstrations, including:

- A high voltage intelligent battery shunt for 400 V and 800 V batteries

- A 40 kW resettable electronic fuse (eFuse) for 400 V and 800 V battery electric vehicles (BEV)

- A unidirectional, 11 kW three-phase AC on-board charger (OBC) with a BOM consisting of 90 % Vishay parts

- A bidirectional 10 kW eFuse for 48 V applicationsA collaborative robot workstation featuring Vishay power resistors, ESTA power electronic capacitors (PEC), Automotive Grade diodes, SiC MOSFETs, and an SiC-based auxiliary power converter.

Vishay passive components on display at PCIM will include IHPT series solenoid-based haptic actuators featuring Immersion Corporation licenses, a 5.5 kW transformer / inductor for LLC applications, and IHLE® series low profile, high current inductors with integrated e-field shields; wirewound resistors and charging resistors featuring hybrid wirewound technology; thick film power resistors; robust metallized polypropylene film capacitors, including AC and pulse capacitors and DC-Link capacitors with high temperature operation up to +125 °C and the ability to withstand temperature humidity bias (THB) testing of 85 °C / 85 % for 1000 h; X1, X2, and Y2 EMI suppression film capacitors certified to safety and humidity robustness grade IIIB; and DC and AC power electronic capacitors (PEC) with high impulse current ratings, low inductance, and high reliability.

Highlighted Vishay semiconductor solutions will consist of surface-mount diodes in the eSMP® and FlatPAK 5×6 packages; leadless surface-mount diodes in the DFN, CLP, and LLP series packages; and 650 V and 1200 V SiC Schottky diodes up to 20 A in eSMP® series and 40 A in power packages for AC/DC power factor correction (PFC) and ultra high frequency output rectification. In addition, Vishay will be showcasing microBUCK® and microBRICK® buck regulators, including the 60 V input SiC967 synchronous buck regulator with integrated power MOSFETs and inductors; high voltage MOSFETs in the PowerPAK 10×12 package; automotive power modules in the EMIPAK 1B, MaacPAK, FlatPAK, and HC0 packages; and industrial power modules in Gen III TO-244, IAP, SOT-227, and MTC packages.

Prior to the exhibition, on June 9, Vishay’s Sanjay Havanur — senior manager of system applications — will be presenting the seminar “Silicon Is Still Here: A Refresher on the Narrow Bandgap Power MOSFETs and Their Datasheets” at 2 p.m. in the Arvena Park Hotel. During the show, Claudio Damilano — director of product marketing and market development, power modules — will present “Evolution in Vishay Power Modules for E-Mobility: Solutions for High Voltage and Low Voltage Applications” on June 11, at 3:50 p.m. in Hall 6, Booth 220.

Original – Vishay Intertechnology

-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / TOP STORIES / WBG3 Min Read

The market for Battery Electric Vehicles (BEVs) and Plug-in Hybrid Electric Vehicles (PHEVs) continues to grow as the push towards decarbonization requires sustainable solutions to reduce emissions. A critical application for EVs is the on-board charger, which converts AC power into DC power to recharge the vehicle’s high-voltage battery.

Microchip Technology announced an On-Board Charger (OBC) solution that uses a selection of its automotive-qualified digital, analog, connectivity and power devices, including the dsPIC33C Digital Signal Controller (DSC), the MCP14C1 isolated SiC gate driver and mSiC™ MOSFETs in an industry-standard D2PAK-7L XL package.

This solution is designed to increase an OBC system’s efficiency and reliability by leveraging the dsPIC33 DSC’s advanced control functions, the MCP14C1 gate driver’s high-voltage reinforced isolation with robust noise immunity and the mSiC MOSFETs’ reduced switching losses and improved thermal management capabilities. To further simplify the supply chain for customers, Microchip provides the key technologies that support the other functions of an OBC, including communication interfaces, security, sensors, memory and timing.

To accelerate system development and testing, Microchip offers a flexible programmable solution with ready-to-use software modules for Power Factor Correction (PFC), DC-DC conversion, communication and diagnostic algorithms. The software modules in the dsPIC33 DSC are designed to optimize performance, efficiency and reliability, while offering flexibility for customization and adaptation to specific OEM requirements.

“Microchip established an E-Mobility megatrend team with dedicated resources to support this growing market, so in addition to providing the control, gate drive and power stage for an OBC, we can also provide customers with connectivity, timing, sensors, memory and security solutions,” said Joe Thomsen, corporate vice president of Microchip’s digital signal controller business unit. “As a leading supplier to OEMs and Tier-1s, Microchip offers comprehensive solutions to streamline the development process, including automotive-qualified products, reference designs, software and global technical support.”

Here is an overview of the key components in this OBC solution:

- The dsPIC33C DSC is AEC-Q100 qualified and features a high-performance DSP core, high-resolution Pulse-Width Modulation (PWM) modules and high-speed Analog-to-Digital Converters (ADCs), making it optimal for power conversion applications. It is functional safety ready and supports the AUTOSAR® ecosystem.

- The MCP14C1 isolated SiC gate driver is AEC-Q100 qualified and is offered in SOIC-8 wide-body package supporting reinforced isolation and SOIC-8 narrow-body supporting basic isolation. Compatible with the dsPIC33 DSC, the MCP14C1 is optimized to drive mSiC MOSFETs via Undervoltage Lockout (UVLO) for VGS = 18V gate drive split output terminals, which simplifies implementation and eliminates the need for an external diode. Galvanic isolation is achieved by leveraging capacitive isolation technology, which results in robust noise immunity and high Common-Mode Transient Immunity (CMTI).

- The mSiC MOSFET in an AEC-Q101-qualified D2PAK-7L XL surface mount package includes five parallel source sense leads to reduce switching losses, increase current capability and decrease inductance. This device supports 400V and 800V battery voltages.

Microchip has published a white paper that provides more information about how this OBC solution can optimize a design’s performance and speed up its time to market.

For more information about Microchip’s OBC solutions for EVs, visit Microchip’s website.

Original – Microchip Technology

-

LATEST NEWS / PRODUCT & TECHNOLOGY / TOP STORIES3 Min Read

Infineon Technologies AG introduced the 600 V CoolMOS™ S7TA Superjunction MOSFET for automotive power management applications. Designed to meet the specific requirements of automotive electronics, the S7TA features an integrated temperature sensor that significantly improves the accuracy of junction temperature sensing, building on the advances made by its counterpart for industrial applications (CoolMOS S7T). The resulting benefits include improved durability, safety, and efficiency, all of which are essential in the automotive domain.

Like its industrial counterpart, the automotive-graded CoolMOS S7TA is particularly well suited for solid-state relay (SSR) applications, demonstrating superior R DS(on) and sensing accuracy, which is crucial for various automotive electronic devices that rely on efficient power management solutions. The integration of a Superjunction MOSFET with an embedded temperature sensor in the same package enhances the performance of SSRs and ensures dependable operation even under the most severe overload conditions, which is an absolute necessity for automotive applications where reliability is non-negotiable.

The embedded sensor of the S7TA offers a 40 percent increase in accuracy and up to four times faster response time than standalone on-board sensors. Such advances in temperature monitoring are critical for automotive applications, enabling individual monitoring within multi-device systems, thereby improving reliability, and preventing thermal issues that can lead to system failures.

The optimized power transistor utilization of the CoolMOS S7TA promises not only superior performance, but also precise control of the output stage. This level of precision is key to reducing power consumption and energy costs, which is a pressing concern in automotive applications where efficiency translates directly into vehicle range and operational economy. Compared to traditional electromechanical relays, the CoolMOS S7TA offers a significant improvement in total power dissipation.

The CoolMOS S7TA further provides a high overcurrent threshold, which serves to increase the reliability of the SSR and reduce the likelihood of failures. The robust switching solution paves the way for safer operations within the vehicle, and the enhanced robustness of the MOSFETs leads to a longer automotive relay lifecycle, resulting in lower maintenance and replacement costs.

The 600 V CoolMOS S7TA provides an optimized solution for potential applications that are central to the safety and functionality of modern vehicles. These include critical components such as circuit breakers, encompassing high-voltage battery disconnect switches, low-frequency switches for both direct current (DC) and alternating current (AC), as well as high-voltage electronic fuses (HV eFuses).

Infineon also introduces the EVAL_eFuse_PoC_400V_S7, a proof-of-concept board that showcases the robustness and versatility of an automotive eFuse. The board demonstrates a reliable method for safeguarding automotive electrical systems, featuring an interchangeable power stage that adapts to various operating conditions with different voltage classes and cooling methods.

Both the 600 V CoolMOS S7T in automotive and industrial grades are already available and come in QDPAK TSC and BSC packages, offering a range of R DS(on) from 17 to 40 mΩ. The 10 mΩ variant will be added to the lineup in the second half of 2024. Further information is available at www.infineon.com/s7ta and www.infineon.com/s7t.

Original – Infineon Technologies

-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / TOP STORIES / WBG3 Min Read

Wolfspeed is expanding its portfolio of industry-leading SiC MOSFET & Schottky diode discrete products with the addition of the new Top Side Cooled (TSC) package: the U2. With options ranging from 650 V – 1200 V, Wolfspeed’s TSC products significantly increase system level power density and efficiency, while improving thermal management and board layout flexibility.

Applications:

- Electric Vehicle (EV) On-Board Chargers and Fast Charging Infrastructure

- EV & Industrial HVAC (Heating, Ventilation, and Air Conditioning) Motor Drives

- High Voltage DC/DC Converters

- Solar and Energy Storage

- Industrial Motor Drives

- Industrial Power Supplies

Features:

- Low profile, surface mount footprint

- Top side cooling with low Rth

- AEC-Q101 Automotive Qualified Options

- SiC MOSFETs Available from 750 V – 1200 V

- SiC Schottky Diodes Available from 650 V – 1200 V

Benefits:

- Highest Creepage Distance Available for SiC Top Side Cooled Packages

- Higher System Power Density with Optimized PCB Layouts

- High Volume Manufacturing Capability with Surface Mount Footprint

What’s New? Advantages of New Top Side Cooled Packages

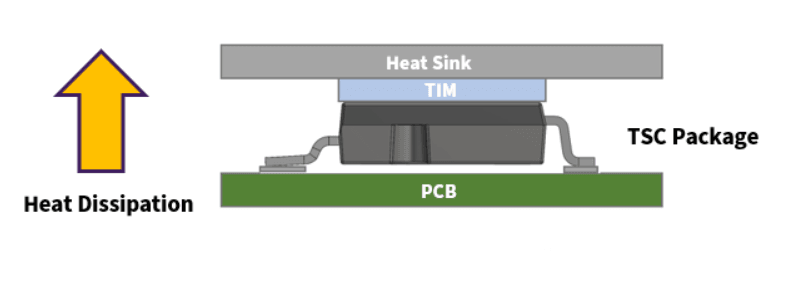

Most standard surface mount discrete power semiconductors remove heat through the bottom of the device by making direct contact with the power circuit board (PCB), which utilizes a heat sink or cooling plate attached underneath. This method is common across many different power electronics applications, particularly when size and weight requirements do not limit PCB mounting and heat sinks.

Top side cooled (TSC) devices, on the other hand, dissipate heat through the top side of the package. Inside TSC packages, the die sits upside down in the upper portion of the package to allow heat to flow directly to the top surface. Generally, TSC devices are best suited for high-performance applications such as automotive and e-mobility systems where high-power densities, advanced thermal management solutions, and small footprints are essential. Within these applications, TSC devices help address cooling requirements by enabling maximum power dissipation and optimizing thermal performance.

TSC designs also allow for dual-side usage of the PCB since the bottom board surface is no longer needed for the heatsink interface. Removing the heatsink from the thermal path not only creates an improved overall system thermal impedance; it also allows for automated assembly, which can increase manufacturing throughput for a more efficient and cost-effective solution.

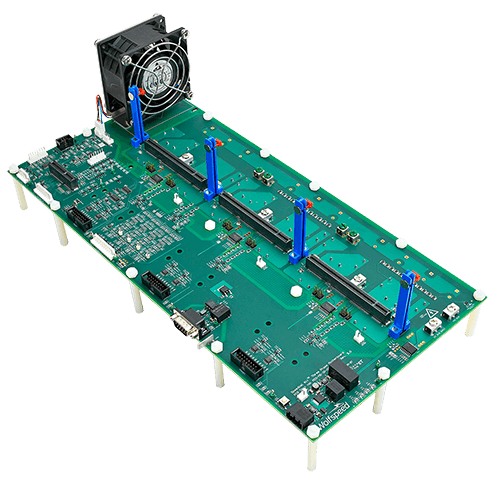

Evaluating U2 TSC Devices Made Easy with SpeedVal™ Kit

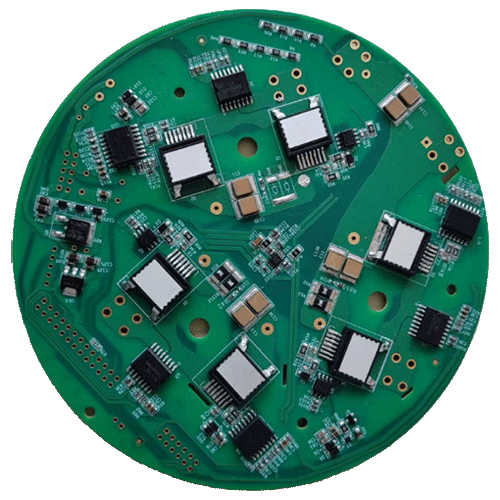

Wolfspeed’s SpeedVal Kit Modular Evaluation Platform allows engineers to reduce the transition from silicon to silicon carbide (SiC) with a flexible set of building blocks for in-circuit evaluation of system performance at real operating points. The recently released 3-phase motherboard enables high-power testing with static loads as well as a foundation for advanced motor control firmware development.

Evaluation boards for a variety of Rdson ratings for Wolfspeed’s TSC MOSFET devices are coming soon.

SpeedVal™ Kit Modular Evaluation Platform Three-Phase Motherboard Putting U2 TSC Devices to Work: 13 kW Automotive HVAC Motor Drive Reference Design

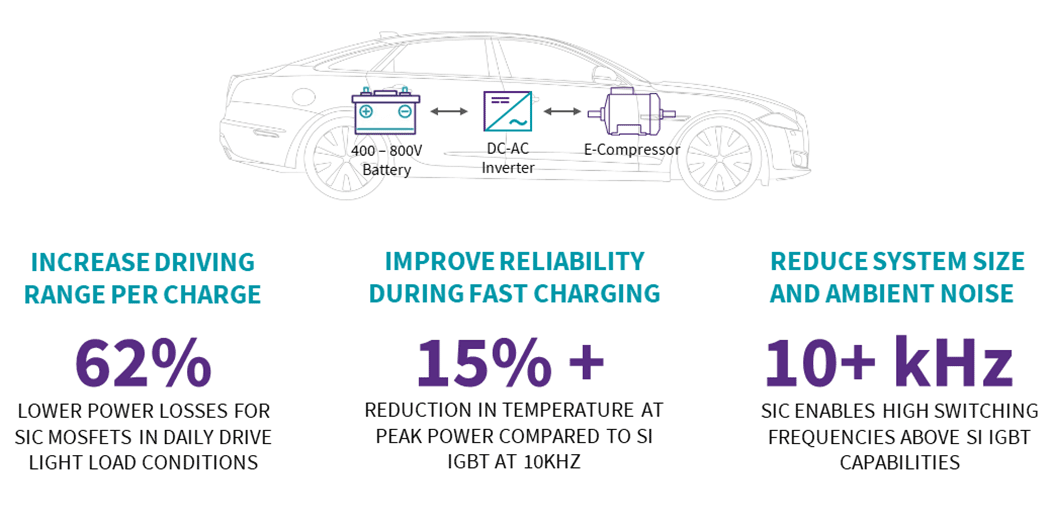

Wolfspeed’s upcoming 13 kW motor drive reference design, featuring the TSC U2 package, demonstrates the benefits of U2 devices for 10 kW+ EV HVAC systems, which support thermal management of the cabin, battery, and electronics. Optimizing the efficiency and operating temperature range of the HVAC system with the implementation of SiC enables systems designers to bring fast charging to the driver in under 15 minutes, while also extending the driving range per charge for the lifetime of the car. Utilizing Wolfspeed’s new CRD-13DA12N-U2 13 kW HVAC reference design, SiC enables:

Reference Design Specifications:

- Input Voltage: 550 – 850 V

- Max Output Current: 25 A

- Max Output Power: 13 kW

- Switching Frequency: 10 – 32 kHz

- Peak Efficiency: > 98%

Original – Wolfspeed