-

LATEST NEWS / PROJECTS / Si / TOP STORIES2 Min Read

Key Foundry signed a long-term supply agreement with Vishay Intertechnology Inc. for multiple power MOSFET products.

Power MOSFETs are the typical power discrete device, characterized by low loss, high-speed switching, and high reliability during high-voltage, high-current operation, which are commonly used in almost every electronic device.

According to a market research firm OMDIA, the power discrete market is expected to grow at a CAGR of 6% from $21.2 billion in 2022, reaching a $28.4 billion market in 2027. Vishay is one of the global leading companies in the power discrete market, and its power semiconductors are widely applied to automotive DC-DC converters, battery management systems, HVAC (Heating, Ventilating, and Air Conditioning) control, LED lighting, as well as consumer and industrial products such as TVs, refrigerators, washing machines, and VR/AR.

Key Foundry and Vishay have signed this long-term foundry service agreement for multiple power MOSFET products, with a plan to start mass production in 2024. In addition, both parties have begun discussions for other future product development.

With this agreement, Vishay secures a reliable source of foundry services for MOSFET production, while Key Foundry engages with a large customer for automotive power discrete, which will increase its share of automotive semiconductor sales in the long term.

“With this agreement we are taking another step forward in our plan to expand capacity, both internally and externally. In particular, it will help us alleviate our current MOSFET supply constraints especially for our automotive and industrial customers,” said Joel Smejkal, President and CEO of Vishay. “In evaluating foundry partners, we decided to engage with Key Foundry because of its foundry’s capabilities and proactive response, and we look forward to the synergies we can achieve through cooperation with Key Foundry.”

“We are pleased to collaborate with Vishay, a leading automotive power semiconductor company,” said Derek D. Lee, CEO of Key Foundry. “Key Foundry will continue to improve process technologies as well as strengthen capabilities in marketing, quality, and production to expand supply of automotive semiconductors and grow into a leading specialty foundry.”

Original – Key Foundry

-

LATEST NEWS / PROJECTS / SiC / TOP STORIES / WBG2 Min Read

Revasum, Inc. announced a strategic partnership with SGSS, a global leader in high-performance materials and innovative solutions. This partnership aims to revolutionize the semiconductor industry by developing a cutting-edge line of grinding wheels specifically designed for Silicon Carbide (SiC) wafers.

Silicon Carbide is a critical material in the production of power devices and has gained significant prominence in the semiconductor industry due to its exceptional properties. The demand for SiC wafers has been steadily growing, and achieving the highest quality wafers is paramount to meet the evolving needs of the market.

The partnership between Revasum and SGSS represents a collaboration between two industry giants with a shared commitment to innovation and excellence. By combining Revasum’s expertise in semiconductor manufacturing equipment with SGSS’s cutting-edge abrasive materials, this alliance seeks to develop a new generation of surface finishing solutions that will set new standards for precision, efficiency, and surface quality in SiC wafer production with sustainability and environmental responsibility at the core of our collaboration.

This partnership holds great promise for the semiconductor industry, paving the way for enhanced SiC wafer production processes that will contribute to the advancement of power electronics, electric vehicles, renewable energy, and various other technology sectors.

Mr. Scott Jewler, CEO of Revasum, Inc., commented on the partnership, saying, “We are excited to join forces with Saint-Gobain Surface Solutions, a renowned leader in materials science and innovation. This partnership will enable us to provide our customers with cutting-edge tools and solutions to address the increasing demand for high-quality Silicon Carbide wafers.”

Mr. Jean-Claude Lasserre, CEO Saint-Gobain Surface Solutions stated, “Our collaboration with Revasum exemplifies our commitment to delivering high-performance materials and solutions that push the boundaries of what is possible. Together, we will unlock new levels of precision and efficiency in Silicon Carbide wafer grinding with highest levels of sustainable products and solutions.”

Both Revasum, Inc. and SGSS are eager to embark on this journey of innovation and look forward to delivering groundbreaking solutions that will shape the future of Silicon Carbide wafer manufacturing.

Original – Revasum

-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / TOP STORIES / WBG2 Min Read

Nexperia has entered into partnership with KYOCERA AVX Components (Salzburg) GmbH to jointly produce a new 650 V, 20 A silicon carbide (SiC) rectifier module for high frequency power applications ranging from 3 kW to 11 kW power stack designs, aimed at application like industrial power supplies, EV charging stations, and on-board chargers. This release will represent a further deepening of the existing, long-lasting partnership between the two companies.

Space-saving and weight reduction are the key requirements for manufacturers of the next generation power applications. The compact footprint of this new SiC rectifier module will help to maximize power density, thereby reducing the amount of required board space and lowering the overall system cost.

Thermal performance is optimized using a combination of top-side cooling (TSC) and an integrated negative temperature coefficient (NTC) sensor which monitors the device temperature and provides real time feedback for device or system level prognosis and diagnosis. This rectifier module has a low inductance package to enable high frequency operation and it has been qualified to operate with a junction temperature of up to 175 °C.

“This collaboration between Nexperia and KYOCERA AVX combines cutting edge silicon carbide semiconductors with state-of-the-art module packaging and will allow Nexperia to better serve the market demand for power electronic products which offer exceptionally high levels of power density,” according to Katrin Feurle, Senior Director of the Product Group SiC at Nexperia. “The release of this rectifier module will represent the first step in what is envisaged as a long-term SiC partnership between Nexperia and KYOCERA AVX”.

Thomas Rinschede, Deputy Vice President Sensing and Control Division at KYOCERA AVX Components Sensing and Control Division, comments: “We are delighted to further extend our successful partnership with Nexperia into the production of silicon carbide modules for power electronics applications. Nexperia’s manufacturing expertise combined with KYOCERA module know-how make a compelling offering for customers looking to achieve higher power densities using wide bandgap semiconductor technology.”

Nexperia expects samples of the new SiC rectifier modules to be available in the first quarter of 2024.

Original – Nexperia

-

LATEST NEWS / PROJECTS / SiC / TOP STORIES / WBG5 Min Read

Hon’ble Union Minister of State for Electronics and Information Technology, Shri Rajeev Chandrasekhar, virtually inaugurated the new Surface Mount Semiconductor Packaging Line, at Continental Device India Private Limited’s (CDIL) Mohali plant today. With the new versatile SMA and SMB package line, via the Government of India’s SPECS, CDIL becomes India’s first Silicon Carbide components manufacturer, scaled to make auto-grade devices, including Silicon Carbide MOSFETs, Silicon Carbide Schottky Diodes, Rectifiers, Zeners and TVS Diodes among others for the global as well as the domestic market. The expansion of assembly lines will increase CDIL’s total capacity at the facility to 600 million units annually.

The new line inauguration was also attended by Shri Tejveer Singh, IAS, Principal Secretary, IT, Government of Punjab, and Shri Amitesh Kumar Sinha, IRAS, Joint Secretary, MeitY and other senior dignitaries of MeitY and Invest Punjab.

With the impending surge in electric vehicles (EVs), power management devices and solar-powered panels, globally as well as in India, and their increased reliance on wide band gap electronics, CDIL identified and laid focus on Silicon Carbide (SiC) products.

SiC is an emerging technology that allows for much-improved efficiencies and power-handling capabilities, especially in high-power charging applications and battery management systems. CDIL spent R&D efforts pursuing SiC technology so as to build proficiency and assist in the world’s switch to Electric Vehicles.

Expressing his gratitude, Tejveer Singh, IAS, Principal Secretary, IT, Government of Punjab, said, “I am very very thankful to the CDIL team for this great effort in expanding the plant capacity and assembly line. And as CDIL and SCL sign the MoU, we can finally see Mohali becoming the chip-making hub of India. The Government has a vision to cultivate a dynamic semiconductor ecosystem in Mohali and therefore, the modernization of SCL could provide the sector the much needed impetus to put Mohali on the semiconductor manufacturing map of India.”

Speaking at the launch of the new assembly lines, Amitesh Kumar Sinha, IRAS, Joint Secretary, MeitY, said, “India’s Semiconductor mission is a key focus for both the Union and the State Governments, and there have been many developments in the sector. Yet, India still has much to catch up, with a projected surge in demand to approximately $110 billion by 2030. At MeitY, our objective is to modernise and commercialise SCL with focus on making it a R&D hub for developing the semiconductor ecosystem in the country.

It’s heartening to see CDIL taking the lead in Packaging of discrete semiconductor devices. CDIL has capability for R&D, Design, and Packaging. Earlier, they also had a fabrication facility. I hope CDIL will also consider setting up a discrete fab in the country by availing financial support under the Semicon India programme in future. As CDIL and SCL join hands for knowledge exchange, India can look forward to more indigenous chip manufacturing and packaging for India and the world in the upcoming future.”

CDIL has also established an advanced testing and reliability laboratory at the Mohali plant. The facility, a one-of-a-kind in India, is equipped to meticulously qualify the semiconductor products according to the stringent standards stipulated by the Automotive Electronics Council (AEC), ensuring they meet the rigorous demands of the automotive domain.

Commenting on the same, Prithvideep Singh, General Manager, CDIL said, “In line with our steadfast commitment to innovation and market diversification, CDIL Semiconductors has strategically positioned itself to meet the burgeoning demands of the automotive sector, both within India and on a global scale. Even though SiC devices are notoriously hard to manufacture at scale, we have spent effort and investment to master them. CDIL has been able to innovate on the brittleness and complexity around the production of SiC devices and has earned the resounding approval of large multinational customers in export markets.”

CDIL also signed an MoU with the Semi-Conductor Laboratory (SCL), a research institute in Mohali under MeitY, undertaking research and development in the field of semiconductor technology. Both parties will aim to establish a comprehensive framework wherein SCL’s specialized knowledge and wafer fabrication facilities are utilized to produce indigenized wafers for CDIL’s discrete semiconductor devices, using CDIL’s proprietary manufacturing processes. This collaborative effort is aimed as a significant stride towards advancing India’s semiconductor ambitions in fostering a stronger, self-reliant industry in the region.

Silicon Carbide (SiC) material boasts a significantly wider bandgap compared to traditional semiconductor materials like silicon. A wide bandgap (~3.26 eV for SiC) enables SiC devices to operate at higher temperatures and handle higher breakdown voltages. Consequently, SiC emerges as the optimal choice for the electric vehicle (EV), power management and solar sectors, as it allows semiconductor components to operate reliably in high temperatures, reducing the need for complex cooling systems.

The company has already initiated pilot production in August with 50 million units and promptly delivered its inaugural batch to customers in both the domestic and international markets. CDIL operates manufacturing facilities and a reliability lab in Mohali and Delhi, serving industries with a strong emphasis on the Automotive, Defence, and Aerospace sectors. With 59 years of legacy, a worldwide customer base, with many industry leaders as loyal customers spread throughout the world including China, Brazil, Germany, Hong Kong, Japan, Malaysia, Russia, Singapore, South Africa, South Korea, Turkey, USA and the UK.

Original – CDIL Semiconductors

-

LATEST NEWS / PROJECTS / SiC / TOP STORIES / WBG2 Min Read

Soitec opened its new plant in Bernin, near Grenoble, in the presence of Thierry Breton, European Commissioner for the Internal Market and Roland Lescure, French Minister Delegate for Industry.

Soitec has developed its SmartSiC™ technology as a response to vehicle electrification challenges.

The technology, based on silicon carbide (SiC), sets a new standard with improved efficiency for energy conversion systems. Thanks to its reduced energy losses, better thermal management and improved power density, the material increases the range and performance of electric vehicles.

Through the application of SmartCut™ technology, each SiC substrate can be used 10 times.

As a result, SmartSiC™ enables electric vehicles to achieve ranges above 500 km, compared with an average 350 km for vehicles using silicon IGBT alternatives – while also reducing CO2 emissions during wafer manufacturing by 70% compared to monocrystalline SiC substrates.

Development of the technology began in 2020 in partnership with CEA-Leti and has received financial support from the French state, the region, local authorities and the European Union.

A new production facility in step with Soitec’s ambition

The new plant will have a 2,500 m2 footprint and a final production capacity of 500,000 SmartSiC™ wafers per year.

It will contribute to Soitec’s strategy of sustainable growth towards a threefold expansion of addressable markets by 2030, reinforcing the company’s leadership position in the strategic semiconductor materials market.

The new plant will lead to the creation of 400 direct jobs, while also reinforcing the attractiveness and dynamism of the “French Silicon Valley” ecosystem.

Pierre Barnabé, Chief Executive Officer of Soitec, stated: “More than ever we are ready to establish our SmartSiC™ technology as a new standard in semiconductor materials for coming generations of electric cars. This plant will enable us to meet growing demand for silicon carbide and achieve a 30% market share by 2030, while helping to make electric mobility more efficient and affordable. Completed in record time, it is the embodiment of our industrial performance and our future-facing strategy, based on the expansion of our product and technology portfolio.

This is also an important day for our region, which is once again showing its dynamic and exemplary approach to industrial innovation, with technologies designed, developed, and manufactured within our ecosystem. We will create jobs and continue to showcase French and European knowhow in global semiconductor markets.”

Original – Soitec

-

LATEST NEWS / TOP STORIES1 Min Read

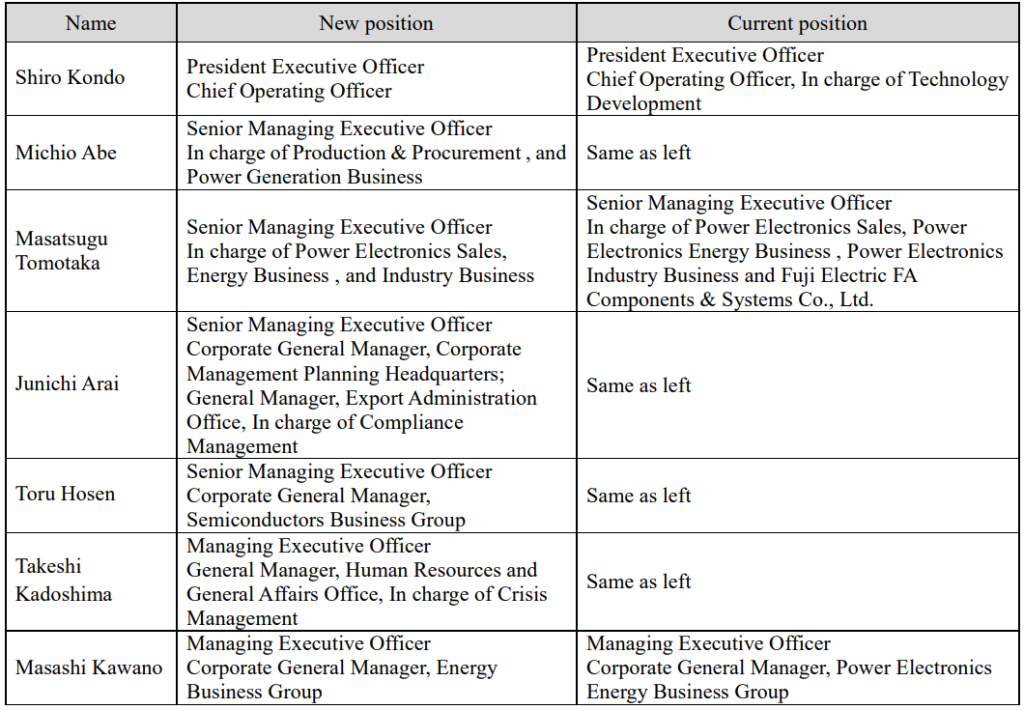

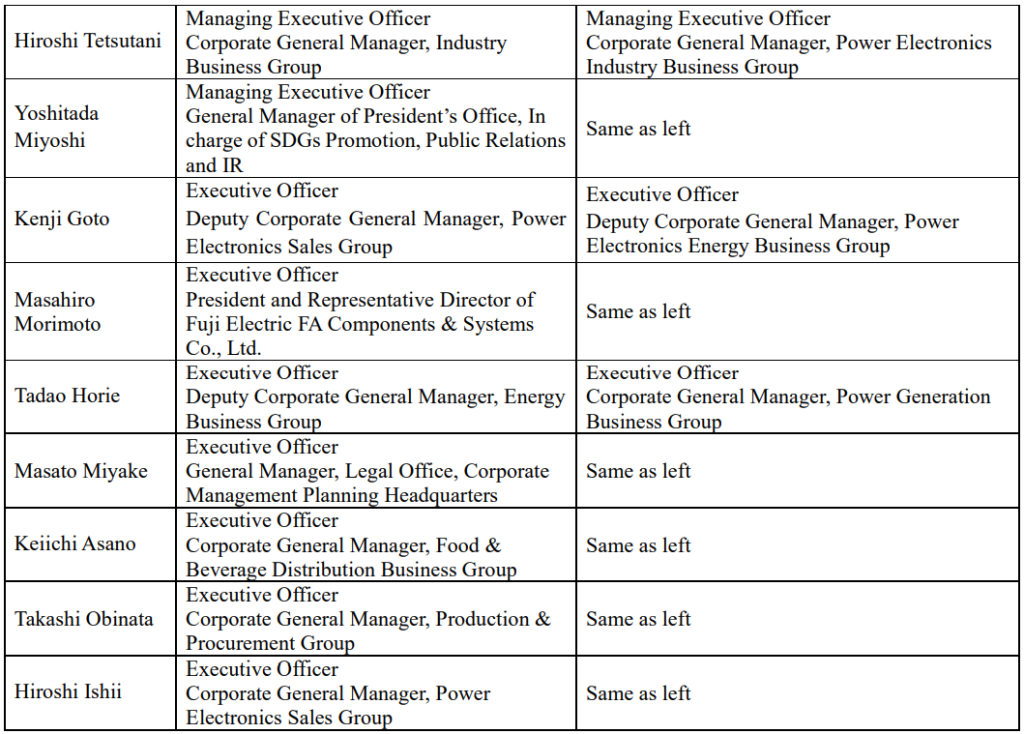

At the meeting of the Board of Directors, Fuji Electric Co., Ltd.’s organizational changes and the appointment of executive officers as of October 1 were resolved. The company will work to strengthen its proposal capabilities in the energy and environment sector by integrating the power electronics and power generation businesses.

Organizational Changes

- The Power Electronics Energy Business Group and the power generation business (thermal & geothermal, hydro, and alternative energy) of the Power Generation Business Group will be integrated to establish the new Energy Business Group.

- The Power Electronics Industry Business Group and the nuclear power business of the Power Generation Business Group will be integrated to establish the new Industry Business Group

Appointment of Executive Officers

Original – Fuji Electric

-

GaN / LATEST NEWS / PRODUCT & TECHNOLOGY / TOP STORIES / WBG2 Min Read

GaN Systems announced the introduction of its groundbreaking 4th generation GaN power platform. This state-of-the-art technology sets a new power efficiency and compactness standard, delivering an impressive step-function performance boost and industry-leading figures of merit. For example, with GaN Systems Gen4 in an artificial intelligence (AI) server rack, 3.2kW power supplies at 100W/in3 in 2022 are now achieving 120W/in3 with efficiencies above Titanium levels. Gen4 will revolutionize power markets, including consumer electronics, data centers, solar energy, industrial applications, and automotive.

The Gen4 platform also delivers more total bill of material cost savings compared to traditional Silicon and Silicon Carbide solutions, making GaN Systems’ technology a powerful choice for businesses seeking to enhance their competitive advantage.

“Our lead customers have already realized the benefits of our Gen4 platform,” stated Jim Witham, CEO of GaN Systems. “This platform is a testament to our ongoing commitment to continuously delivering superior performance advantages and next-generation levels of efficiency. GaN Systems, in strategic collaboration with industry leaders like TSMC, has invested significantly to meet the ever-evolving demands of our customers. We are pioneering a transformation in product offerings, packaging innovations, enriched functionalities, and unparalleled performance across our markets.”

A Huge Leap for Power Electronics Technology

The Gen4 power platform boasts the following benefits:

- >20% improvement in input and output figures-of-merit translates into reduced losses, enhanced efficiency, and more cost-effective solutions.

- Increased granularity in device specification, combined with a wide range of packaging options, including PDFN, TOLL, TOLT, and Embedded – allowing the correct Rds resistance and package combination for each application, consequently optimizing electrical and thermal system performance.

- 700V E-mode with the industry’s highest transient voltage rating, 850V, significantly enhancing total system reliability and robustness. This rating enables the semiconductor components to withstand user environment anomalies, such as voltage spikes, ensuring uninterrupted and dependable performance.

- On-state resistance ranges enable power systems from 20W to 25,000W.

For more information, visit https://gansystems.com/gan-transistors/gen-4/

Original – GaN Systems

-

GaN / LATEST NEWS / PRODUCT & TECHNOLOGY / TOP STORIES / WBG3 Min Read

Researchers at the Indian Institute of Science (IISc) have developed a fully indigenous gallium nitride (GaN) power switch that can have potential applications in systems like power converters for electric vehicles and laptops, as well as in wireless communications. The entire process of building the switch – from material growth to device fabrication to packaging – was developed in-house at the Centre for Nano Science and Engineering (CeNSE), IISc.

Due to their high performance and efficiency, GaN transistors are poised to replace traditional silicon-based transistors as the building blocks in many electronic devices, such as ultrafast chargers for electric vehicles, phones and laptops, as well as space and military applications such as radar.

“It is a very promising and disruptive technology,” says Digbijoy Nath, Associate Professor at CeNSE and corresponding author of the study published in Microelectronic Engineering. “But the material and devices are heavily import-restricted … We don’t have gallium nitride wafer production capability at commercial scale in India yet.” The know-how of manufacturing these devices is also a heavily-guarded secret with few studies published on the details of the processes involved, he adds.

Power switches are used to control the flow of power to – essentially turn on or off – electronic devices. To design the GaN power switch, the IISc team used a metal organic chemical vapour deposition technique developed and optimised over a decade by researchers in the lab of Srinivasan Raghavan, Professor and Chair, CeNSE. It involves growing GaN alloy crystals layer by layer on a two-inch silicon wafer to fabricate a multi-layered transistor.

The entire process needs to be carried out carefully in a clean room to ensure that no defects arise due to environmental conditions like humidity or temperature, which can affect device performance. The team also took the help of Kaushik Basu, Associate Professor in the Department of Electrical Engineering (EE), and his lab, to build an electrical circuit using these transistors and test their switching performance.

GaN transistors typically operate in what is called a “depletion mode” – they are on all the time unless a negative voltage is applied to turn them off. But power switches used in chargers and adapters need to work the other way around – they normally need to be off and not carrying current, and should only turn on when a positive voltage is applied (“enhancement mode”). To achieve this operation, the team combined the GaN transistor with a commercially available silicon transistor to keep the device normally off.

“The packaging of the device was also indigenously developed,” explains Rijo Baby, PhD student at CeNSE and first author of the study. After packaging and testing, the team found the device performance to be comparable to state-of-the-art switches available commercially, with a switching time of about 50 nanoseconds between on and off operations.

Going forward, the researchers plan on scaling up the device dimensions so that it can operate at high currents. They also plan to design a power converter that can step up or step down voltages.

“If you look at strategic organisations in India, they have a hard time procuring GaN transistors … It is impossible to import them beyond a certain quantity or power/frequency rating,” says Nath. “This is essentially a demonstration of indigenous GaN technology development.”

Original – Indian Institute of Science (IISc)

-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / TOP STORIES / WBG2 Min Read

Bourns, Inc. has expanded its 650 and 1200 V Silicon Carbide (SiC) Schottky Barrier Diode (SBD) product family with 10 new models. The 10 new models added to the Bourns® SiC SBD line are designed to address the increasing power density requirements in the latest transportation, renewable energy and industrial systems.

Bourns’ expanded wide band gap diode line delivers the peak forward surge, low forward drop, reduced thermal resistance and low power loss capabilities demanded by today’s high frequency and high current applications. These capabilities also help designers develop smaller, cost-efficient and state-of-the-art power electronics.

As optimal power conversion solutions for DC-DC and AC-DC converters, Switched-Mode Power Supplies (SMPS), photovoltaic inverters, motor drives and other rectification applications, the 10 new models feature currents in the 5-10 A range, with no reverse recovery current to reduce EMI.

This enables them to significantly lower energy losses and further increase efficiency, switching performance and reliability. In addition to providing excellent thermal performance, Bourns’ new SiC SBD models are available in multiple forward voltage, current and package options that include TO220-2, TO247-3, TO252, TO263 and TO247-2.

The 10 new Bourns® BSD SiC SBD models are available now. These models are RoHS compliant, halogen free, Pb free and their epoxy potting compound is flame retardant to the UL 94V-0 standard. For more detailed product information, please see: www.bourns.com/products/diodes/silicon-carbide-sic-schottky-barrier-diodes.

Original – Bourns

-

LATEST NEWS / SiC / TOP STORIES / WBG4 Min Read

During the past decade combination “silicon carbide” or more often “SiC” has become very popular in the world of power electronics. Many companies have started to evaluate the possibility of using SiC instead of Si in their projects. As many say, silicon carbide is here to replace silicon, and they might be right considering that SiC MOSFETs used in power semiconductor devices bring numerous advantages compared with their silicon counterparts.

SiC has a higher critical breakdown field and thermal conductivity and, a wider bandgap, which leads to lower energy losses, a lower leakage current at higher temperatures. Besides, SiC can operate at much higher frequencies. On a system level, it means using less additional components, better thermal management, and an overall smaller footprint.

This is one of the reasons why today automotive Tier-1 and OEM companies prefer to use SiC for their new projects in vehicle electrification. With SiC they can get the same efficiency with several times smaller package. For the electric car size and weight of power electronics systems are critical.

Working in the power semiconductors industry for many years, with Si and SiC power devices in particular, I see that the number of companies and end applications adopting silicon carbide is growing fast. Even though SiC is quite a young technology, and the first commercial SiC power MOSFET dates back to 2011, nowadays, we already have over ten SiC power device vendors who deliver high-quality products used in electric vehicles, solar inverters, public transportation, welding equipment, marine, medical and aerospace.

With the number of new SiC fabs and production expansions announced during the past three years it is clear that silicon carbide technology is here to stay, and here to grow further. Many analytical agencies predict that the total SiC market will reach 10 billion USD by 2030 or even earlier. And despite the fact that in volume SiC power semiconductors market still lags behind silicon. It grows faster, quite faster than expected several years ago.

Despite the fast growth and penetration into the power electronics market, many companies still feel uncomfortable when they hear about silicon carbide and the benefits it has. During numerous negotiations and talks with the companies using power semiconductor devices, I shortlisted the most common barriers preventing them from switching from silicon to silicon carbide, or from increasing the number of SiC-based projects they already have.

To further scale this data, recently I had a poll on LinkedIn within the power electronics community. A similar poll I ran during the latest EPE’23 ECCE Europe Conference, which was held in Aalborg, Denmark. Both polls’ participants come from power semiconductors companies or from companies using power semiconductors.

Combined poll results look like this:

- Price – 60%

- Availability – 20%

- Unclear benefits over Si – 7%

- Not enough market feedback – 13%

It is clear that price is still the major concern and barrier. Even though the price has tremendously decreased during the past ten years, it remains one of the key factors why many companies prefer to use Si-based semiconductors.

The availability of SiC wafers or SiC-based devices accounts for another 20% of doubts coming from the end users. The lead time of SiC has been discussed many times, and the situation for many stays unclear. And it is the same for the remaining 20% of poll results coming from unclear benefits of SiC and lack of market feedback. Silicon power devices have been in use for decades, while SiC is just at the beginning of its road. That is why many engineers prefer to work with the technology they know, the technology they have been very familiar with since their school.

From the first look the answers and results of the poll seem to be right and they correspond to the current market situation. However, working with Si and SiC, I know that each and every one of the answers listed are just the barriers and not the final verdict.

Semiconductor companies should pay more attention to those 20% of the answers referring to lack of market data. With the right approach SiC will bring the power semiconductors industry to a new level.