-

LATEST NEWS / PRODUCT & TECHNOLOGY / Si / TOP STORIES1 Min Read

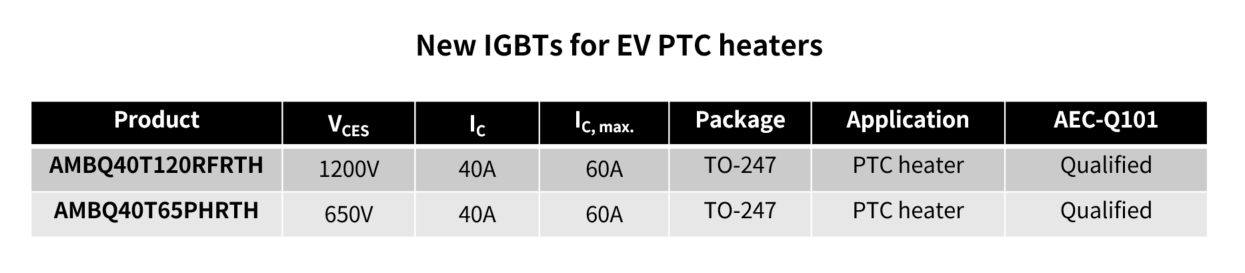

Magnachip Semiconductor Corporation announced the launch of its 1200V and 650V Insulated Gate Bipolar Transistors (IGBTs), designed for the positive temperature coefficient (PTC) heaters of electric vehicles (EVs).

Built upon Magnachip’s cutting-edge Field Stop Trench technology, the newly introduced AMBQ40T120RFRTH (1200V) and AMBQ40T65PHRTH (650V) offer a minimum short-circuit withstand time of 10µs. This remarkable level of ruggedness enables PTC heaters to be protected from a permanent failure in the event of overcurrent conditions.

Furthermore, the thick and large heat sink of the TO-247 package allows these new IGBTs to excel in heat dissipation. Therefore, these IGBTs are well-suited for applications requiring high power and efficiency, such as both the upper and lower sides of power management integrated circuits of PTC heaters.

“Since early last year, Magnachip has released high-performance automotive power solutions that adhere to the stringent AEC-Q101 standards,” said YJ Kim, CEO of Magnachip. “Now that we have successfully released our first IGBT products for EVs, we will continue to expand our product lineup to meet the diverse needs of the EV market and cater to the demands of our valued customers.”

Original – Magnachip Semiconductor

-

LATEST NEWS / PROJECTS / TOP STORIES3 Min Read

A group of semiconductor companies in Flanders have come together to create Flanders Semiconductors, a new nonprofit organization representing the interests of the industry at local, European, and global levels. The organization is open to all qualifying companies, both in and outside of the Flanders region, that have semiconductor technology at the core of their business.

Flanders Semiconductors is a significant move for the Flemish semiconductor industry, which currently employs well over 3,000 people directly, has more than 50 companies with semiconductor as their core business, and over 100 companies defining, testing, and integrating advanced customized semiconductor devices or technologies.

Flanders Semiconductors covers the whole supply chain, including infrastructure, equipment, materials, processing, testing, and devices. The Flanders region also boasts world-class research facilities such as IMEC, universities, and institutes providing semiconductor R&D, education, and training. The objectives of Flanders Semiconductors are to increase the talent pool, share industry roadmaps, maintain a yearly business events calendar, and represent members’ interests at international levels. The organization will also market the region and its members internationally, to promote cooperation between members and to cooperate with similar organizations in Europe.

Flanders Semiconductors is led by President Lou Hermans, who has over three decades of industry expertise, along with a team of seasoned semiconductor professionals. Together with the dedicated management team, their mission is to foster collaboration, drive innovation, and catalyze growth within the semiconductor ecosystem, both in Flanders and on a global scale.

“We are thrilled to officially announce the launch of Flanders Semiconductors, poised to be(come) another important European hub for semiconductor innovation,” said Lou Hermans, President of Flanders Semiconductors. “Our founding members, including BelGan, Caeleste, Cochlear, easics, ICsense, NXP, Pharrowtech, Sofics, and Spectricity, have united to create a platform that champions the semiconductor industry’s interests at every level. I am deeply inspired and motivated by the drive, support, remarkable power and unity of the founding members. Our diverse community of present and future member companies, each bringing their unique solutions to the semiconductor industry, exemplifies the immense strength and boundless potential that collaboration holds.”

Flanders Semiconductors welcomes all qualifying companies with semiconductors as their main business and is open to associate memberships for universities, R&D organizations, and non-qualifying companies.

The grand unveiling of the Flanders Semiconductor association is set for September 13th in Leuven, Belgium and interested parties can join this special occasion. Registrations to secure a spot can be done at www.flanders-semiconductors.org

Original – Flanders Semiconductors

-

GaN / LATEST NEWS / PRODUCT & TECHNOLOGY / TOP STORIES / WBG4 Min Read

Navitas Semiconductor announced the world-wide launch of GaNSafe™, a new, high-performance wide bandgap power platform at a special customer, partner and press event in Taiwan. Navitas has optimized its 4th-generation gallium nitride technology for demanding, high-power applications in data centers, solar / energy storage and EV markets, where efficiency, power density and robust & reliable operation are critical.

At the worldwide launch event at the Marriot Taipei, Navitas’ David Carroll, Sr. VP Worldwide Sales, and Charles Bailley, Sr. Director Business Development will introduce Navitas and the new GaNSafe platform to an invited VIP audience of over 50 high-ranking customer attendees, plus industry partners and international media.

The new 4th-generation GaN power ICs are manufactured in Hsinchu, by long-term Navitas partner TSMC. Navitas is grateful to Dr. RY Su, Manager of GaN Power Technology at TSMC, who will make a special presentation on the future of GaN at the GaNSafe launch.

Navitas’ GaNFast™ power ICs integrate gallium nitride (GaN) power and drive, with control, sensing, and protection to enable faster charging, higher power density, and greater energy savings, with over 100,000,000 units shipped, and an industry-first 20-year warranty. Now, the new GaNSafe platformhas been engineered with additional, application-specific protection features, functions and new, high-power packaging to deliver enabling performance under grueling high-temperature, long-duration conditions.

The initial, high-power 650/800 V GaNSafe portfolio covers a range of RDS(ON) from 35 to 98 mΩ in a novel, robust, and cool-running surface-mount TOLL package, to address applications from 1,000 to 22,000 W. GaNSafe integrated features and functions include:

- Protected, regulated, integrated gate-drive control, with zero gate-source loop inductance for reliable high-speed 2 MHz switching capability to maximize application power density.

- High-speed short-circuit protection, with autonomous ‘detect and protect’ within 50 ns – 4x faster than competing discrete solutions.

- Electrostatic discharge (ESD) protection of 2 kV, compared to zero for discrete GaN transistors.

- 650 V continuous, and 800 V transient voltage capability to aid survival during extraordinary application conditions.

- Easy-to-use, complete, high-power, high-reliability, high-performance power IC with only 4 pins, to accelerate customer designs.

- Programmable turn-on and turn-off speeds (dV/dt) to simplify EMI regulatory requirements.

Unlike discrete GaN transistor designs, with voltage spikes, undershoot and specification breaches, GaNSafe delivers an efficient, predictable, reliable system. GaNSafe’s robust 4-pin TOLL package has achieved the tough IPC-9701 mechanical reliability standard, and delivers simple, strong, dependable performance as compared to multi-chip modules which require 3x as many connections, and have poor cooling capability.

Navitas’ market-specific system design centers offer complete platform designs with benchmark efficiency, density and system cost using GaNSafe products to accelerate customer time-to-revenue and maximize chance of first-time-right designs. These system platforms include complete design collateral with fully-tested hardware, embedded software, schematics, bill-of-materials, layout, simulation and hardware test results. Examples of system platforms enabled by GaNSafe technology include:

- Navitas’ CRPS185 data center power platform, that delivers a full 3,200 W of power in only 1U (40 mm) x 73.5mm x 185 mm (544 cc), achieving 5.9 W/cc, or almost 100 W/in3 power density. This is a 40% size reduction vs, the equivalent legacy silicon approach and reaches over 96.5% efficiency at 30% load, and over 96% stretching from 20% to 60% load, creating a ‘Titanium Plus’ benchmark.

- Navitas’ 6.6 kW 3-in-1 bi-directional EV on-board charger (OBC) with 3 kW DC-DC. This 96%+ efficient unit has over 50% higher power density, and with efficiency over 95%, delivers up to 16% energy savings as compared to competing solutions.

“Our original GaNFast and GaNSense technologies have set the industry standard for mobile charging, establishing the first market with high-volume, mainstream GaN adoption to displace silicon,” said Gene Sheridan, CEO and co-founder. “GaNSafe takes our technology to the next level, as the most protected, reliable and safe GaN devices in the industry, and now also targeting 1-22 kW power systems in AI-based data centers, EV, solar and energy storage systems. Customers can now achieve the full potential of GaN in these multi-billion dollar markets demanding the highest efficiency, density and reliability.”

The GaNSafe portfolio is available immediately to qualified customers with mass production expected to begin in Q4 2023. 40 customer projects are already in progress with GaNSafe in data center, solar, energy storage and EV applications, contributing to Navitas’ $1 billion customer pipeline.

Original – Navitas Semiconductor

-

GaN / LATEST NEWS / PRODUCT & TECHNOLOGY / TOP STORIES / WBG3 Min Read

Shin-Etsu Chemical Co., Ltd. has determined that QST® (Qromis Substrate Technology) substrate is an essential material for the social implementation of high-performance, energy-efficient GaN (gallium nitride) power devices, and the company will promote the development and launching on the market of these products.

Since QST® substrate is designed to have the same coefficient of thermal expansion (CTE) as GaN, it enables suppression of warpage and cracking of the GaN epitaxial layer and resultant large-diameter, high-quality thick GaN epitaxial growth. Taking advantage of these characteristics, it is expected to be applied to power devices and RF devices (5G and beyond 5G), which have been rapidly growing in recent years, as well as in such areas as MicroLED growth for MicroLED displays.

In addition to sales of QST® substrates, Shin-Etsu Chemical will also sell GaN grown QST® substrates upon customer request. We currently have a line-up of 6″ and 8″ diameter substrates, and we are working on 12″ diameter substrates. Since 2021, for each respective application for power devices, RF devices and LEDs, sample evaluation and device development are continuing with numerous customers in Japan and globally. Especially for power devices, continuous evaluation is underway for devices in the wide range of 650V to 1800V.

So far, Shin-Etsu Chemical has repeatedly made many improvements with regard to its QST® substrates. One example is the significant improvement in lowering defects originating from the bonding process, which has enabled the supply of high-quality QST® substrates. In addition, for the thicker GaN films that many of our customers have requested, we have promoted the provision of template substrates with optimized buffer layers, which enables our customers to realize stable epitaxial growth of more than 10 μm thickness. Furthermore, various successful results have been produced and reported on, including the achievement of thick-film GaN growth exceeding 20 μm using QST® substrates and the achievement of 1800V breakdown voltage in power devices.

Moreover, Shin-Etsu Chemical and Oki Electric Industry Co., Ltd. have jointly succeeded in developing a technology to exfoliate GaN from QST® substrates and bond it to substrates made of different materials using Crystal Film Bonding (CFB) technology. Until now, most GaN power devices have been lateral devices, but CFB technology takes advantage of the characteristics of QST® substrates to realize vertical power devices that can control large currents by exfoliating a thick layer of high-quality GaN from an insulating QST® substrate (see figure below).

To customers who manufacture GaN devices, Shin-Etsu Chemical will provide QST® substrates or GaN grown QST® substrates and Oki Electric Industry will provide its CFB technology through partnering or licensing. In this way, the two companies hope to contribute to the advancement of vertical power devices.

Based on these development results and also based on business situation inquiries from customers, Shin-Etsu Chemical will continue to increase production to meet customer demand.

Shin-Etsu Chemical will contribute to the realization of a sustainable society that can use energy efficiently by further promoting the social implementation of GaN devices that have characteristics that are absolutely essential for the future society.

Original – Shin-Etsu Chemical

-

LATEST NEWS / PROJECTS / SiC / TOP STORIES / WBG2 Min Read

On the road towards becoming a fully electric car maker by 2030, an important focus area for Volvo technology investments and R&D spending is e-motors, inverters and overall electric drivetrain optimisation.

Only by gaining control over electrification technology stack – a process called “vertical integration” – can can a company create pure electric Volvo cars that deliver on everything the customers want: longer range, faster charging and a great Volvo driving experience.

The latest investment by the Volvo Cars Tech Fund, the corporate venture capital arm, reflects those ambitions. Leadrive, a Shanghai-based company founded in 2017, is an exciting new player in power electronics and control units for fully electric cars.

Leadrive is specialising in designing and building power modules that use silicon carbide (SiC) technology. Silicon carbide is a semiconductor base material that promises to unlock highly efficient and flexible electric propulsion systems.

“Leadrive’s technology demonstrates a lot of potential for the development of more efficient electric drivetrains,” said Alexander Petrofski, CEO of the Volvo Cars Tech Fund. “That potential closely aligns with our own focus on electrification, so we’re excited to invest in the company and help it to continue growing its business.”

“Volvo Cars and Leadrive have been working very closely on the development of new generation SiC technologies, which has built a firm stairway towards the strategic collaboration,” said Jie Shen, founder and CEO of Leadrive. “This is a great milestone in Leadrive’s global strategy and demonstrates the huge potential of our cooperation in advanced electrification technology.”

Original – Volvo Car Corporation

-

LATEST NEWS / PRODUCT & TECHNOLOGY / Si / TOP STORIES1 Min Read

STMicroelectronics has released a new class of IGBTs with an increased breakdown-voltage capability of 1350V and maximum operating temperature of 175°C. The higher ratings ensure greater design margin, robust performance, and extended reliability under all operating conditions.

The new STPOWER IH2 series IGBTs also permit increased power-conversion efficiency. Favorable parameters include low saturation voltage, Vce(sat), which ensures low dissipation when the device is turned on. The freewheeling diode has low voltage drop and optimized turn-off energy that increases the efficiency of single-switch quasi-resonant converters operating at frequencies from 16kHz to 60kHz.

With their ruggedness and high efficiency, these IGBTs are ideal for induction-heating applications including domestic appliances such as kitchen hobs, inverter microwave ovens, and rice cookers. In a 2kW application, ST’s new IGBT devices can reduce power dissipation by up to 11%.

In addition, the Vce(sat) has a positive temperature coefficient and tight parameter distribution between devices helps simplify design and ease connecting multiple IGBTs in parallel to address high-power applications.

The first two devices in the series, the 25A STGWA25IH135DF2 and 35A STGWA35IH135DF2, are in production now and available in a standard TO-247 long-lead power package.

Original – STMicroelectronics

-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / TOP STORIES / WBG1 Min Read

The new Vincotech 1200 V flowCSPFC S3 SiC module featuring current-synthesizing PFC (CS-PFC) topology based on the constant power control, strikes the best balance between performance and system cost to benefit your business.

The first module of this new product family is well suited for a DC fast charger PFC converter stage up to 35kW power, a “sweet spot” for building scalable DC charger units on a modular approach.

Main benefits

- Current-synthesizing PFC slashes module costs by > 25% with conversion efficiencyranging as high as >99%

- System costs come down with fewer and smaller inductors on the PCB

- No large electrolytic DC-link capacitors for even more system-level savings

- Pinout is ready for bidirectional applications and optimized for easy PCB routing

- High power density for compact designs and fast charging

Applications

- EV fast charger

- UPS

- ESS

Original – Vincotech

-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / TOP STORIES / WBG3 Min Read

McLaren Applied has launched IPG5-x, a highly flexible 800V Silicon Carbide (SiC) inverter that can be integrated into Electric Drive Units (EDUs). Targeting growing OEM demand for high-performing, integrated EDUs that save space and cost, the British engineering and technology pioneer has developed IPG5-x to work with a variety of motors and transmissions – especially in performance applications.

IPG5-x is an adaptation of McLaren Applied’s current award-winning 800V SiC inverter, IPG5. IPG5-x will coexist alongside the standalone IPG5, with application depending on customer need. The ‘x’ suffix was chosen because IPG5-x is a product designed for collaboration with Tier 1 and OEM partners looking to bring EDU products to market quickly and cost effectively. McLaren Applied is in discussions with several OEMs and Tier 1 suppliers, and is working with transmission provider TREMEC to jointly develop an integrated EDU for their first customer vehicle application.

“In our discussions with customers and partners, it’s become clear that OEMs are increasingly looking for the option to source integrated EDUs that save space, cost and speed up development time,” commented Paolo Bargiacchi, Head of Product, Automotive at McLaren Applied. “We’ve developed the IPG5-x to be highly flexible, so it’s ready to be integrated within any combination of motor and transmission. It carries over all of our standalone IPG5’s qualities – peak efficiencies over 99%, continuously variable switching and fine motor control – building on the maturity of that product.”

Derived from decades of innovation in top tier automotive and motorsports, McLaren Applied’s IPG5-x offers best-in-class fine motor control and high efficiency through continuously variable switching frequencies; maximising the advantages of SiC semiconductors.

The IPG5-x forms a step forward in what the automotive team at McLaren Applied describes as the ‘waves of electrification’. The first wave involved early pioneers of technology, the second wave is denoted by the breakthrough of EVs to the mainstream. The third wave is efficiency and will see inverter technology rapidly adopt SiC semiconductors, especially in 800V architectures, enabling vehicles to achieve longer range where efficient power electronics are key.

Bargiacchi added: “The immediate focus must be on achieving greater drivetrain efficiency and cost reduction, which you can do through a product like IPG5-x. The competitive landscape is ramping up significantly now that all manufacturers have established their product entry points.

“Models based on dedicated 800V SiC architectures are leading the way, driving a virtuous cycle: an efficient drivetrain inherently has a smaller battery, which makes the vehicle cheaper, lighter and easier to control, and offers a smaller embedded and operating carbon footprint. It also increases range and speeds up charge times, building trust in the technology.”

As competition increases, we will enter the fourth wave, where OEMs will need to differentiate the customer experience their products deliver. In anticipation of this change, McLaren Applied has developed advanced motor control software in both IPG5 and IPG5-x that enables a variety of features ranging from improved refinement through to a more engaging drive.

Original – McLaren Applied

-

LATEST NEWS / SiC / TOP STORIES / WBG2 Min Read

STMicroelectronics will supply BorgWarner Inc. with the latest third generation 750V silicon carbide (SiC) power MOSFETs dice for their proprietary Viper-based power module. This power module is used in BorgWarner’s traction inverter platforms for several current and future Volvo Cars electric vehicles.

“This collaboration will give Volvo Cars the opportunity to further increase the attractiveness of our electrical vehicles with longer range and faster charging. It will also support us on our journey towards being fully electric by 2030 and strengthen our increased vertical integration and our control of critical components,” says Javier Varela, Chief Operating Officer & Deputy CEO, Volvo Cars.

“BorgWarner is pleased to partner with ST to supply our longstanding customer Volvo Cars with inverters for their next generation of BEV platforms,” says Stefan Demmerle, Vice President of BorgWarner Inc. and President and General Manager, PowerDrive Systems.

To fully leverage the performance of ST’s SiC MOSFET dice, BorgWarner collaborated closely with ST’s technical team to match their die with BorgWarner’s Viper power switch, thereby maximizing inverter performance and delivering a compact and cost-effective architecture. The collaboration between the companies provides the high-volume capability that is required by the quickly growing EV market.

“Our collaboration with BorgWarner, a leading global automotive supplier in electrification, will enable Volvo Cars to offer their customers superior vehicle performance and range,” says Marco Monti, President, Automotive and Discrete Group, STMicroelectronics. “We are committed to expanding SiC capacity and to reinforcing our SiC supply, including through vertical integration, as we ramp up volumes to support our global automotive and industrial customers in their shift to electrification and higher efficiency.”

ST’s high-volume STPOWER SiC products are manufactured in its fabs in Italy, and Singapore, with advanced packaging and testing at its back-end facilities in Morocco and China. In October 2022, ST announced it would expand its wide bandgap manufacturing capacity with a new integrated SiC substrate manufacturing facility in Catania, home to the company’s power semiconductor expertise and the site of integrated research, development, and manufacturing of SiC.

Original – STMicroelectronics

-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / TOP STORIES / WBG2 Min Read

Toshiba Electronic Devices & Storage Corporation has launched silicon carbide (SiC) MOSFETs, the “TWxxxZxxxC series,” that use a four-pin TO-247-4L(X) package that reduces switching loss with the company’s latest 3rd generation SiC MOSFETs chip for industrial equipment. Volume shipments of ten products, five with 650V ratings and five with 1200V, start today.

The new products are the first in Toshiba’s SiC MOSFET line-up to use the four-pin TO-247-4L(X) package, which allows Kelvin connection of the signal source terminal for the gate drive. The package can reduce the effect of source wire inductance inside the package, improving high-speed switching performance. For the new TW045Z120C, the turn-on loss is approximately 40% lower and the turn-off loss reduced by approximately 34%, compared with Toshiba’s current product TW045N120C in a three-pin TO-247 package. This helps to reduce equipment power loss.

Applications

- Switching power supplies (servers, data centers, communications equipment, etc.)

- EV charging stations

- Photovoltaic inverters

- Uninterruptible power supplies (UPS)

Features

- Four-pins TO-247-4L(X) package:

Switching loss is reduced by Kelvin connection of the signal source terminal for the gate drive - 3rd generation SiC MOSFETs

- Low drain-source On-resistance x gate-drain charge

- Low diode forward voltage: VDSF=-1.35V (typ.) (VGS=-5V)

Original – Toshiba