-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / WBG2 Min Read

Many industrial applications today are moving towards higher power levels with minimized power losses. One way to achieve this is to increase the DC link voltage. Infineon Technologies AG is addressing this market trend with the CoolSiC™ Schottky diode 2000 V G5 product family, the first discrete silicon carbide diodes with a breakdown voltage of 2000 V, introduced in September 2024.

The product portfolio has now been expanded to include a Schottky diode in the TO-247-2 package, which is pin-compatible with most existing TO-247-2 packages. The product family fits perfectly for applications with DC link voltages up to 1500 V DC, making it ideal for solar and EV chargers.

The CoolSiC Schottky diode 2000 V G5 in the TO-247-2 package is available with current ratings ranging from 10 to 80 A. It allows developers to achieve higher power levels in their applications while reducing the component count by half compared to 1200 V solutions. This simplifies the overall design and facilitates a seamless transition from multi-level to two-level topologies.

In addition, the Schottky diode in the TO-247-2 package incorporates .XT interconnection technology, which significantly reduces thermal resistance and impedance, thereby enhancing heat management. Humidity robustness has been validated through HV-H3TRB reliability testing. The diodes exhibit neither reverse recovery nor forward recovery, and feature a low forward voltage, ensuring improved system performance.

The 2000 V diode family is a perfect match for the CoolSiC MOSFETs 2000 V in the TO-247Plus-4 HCC package that Infineon launched in the spring of 2024. In addition to the TO-247-2 package, the CoolSiC Schottky Diode 2000 V is also available in the TO-247PLUS-4 HCC package.

Original – Infineon Technologies

-

LATEST NEWS / PRODUCT & TECHNOLOGY / SiC / WBG4 Min Read

NoMIS Power has announced a major breakthrough in improving the short-circuit withstand time (SCWT) of SiC MOSFETs. This innovation addresses one of the key challenges limiting the widespread adoption of SiC technology in high-power applications.

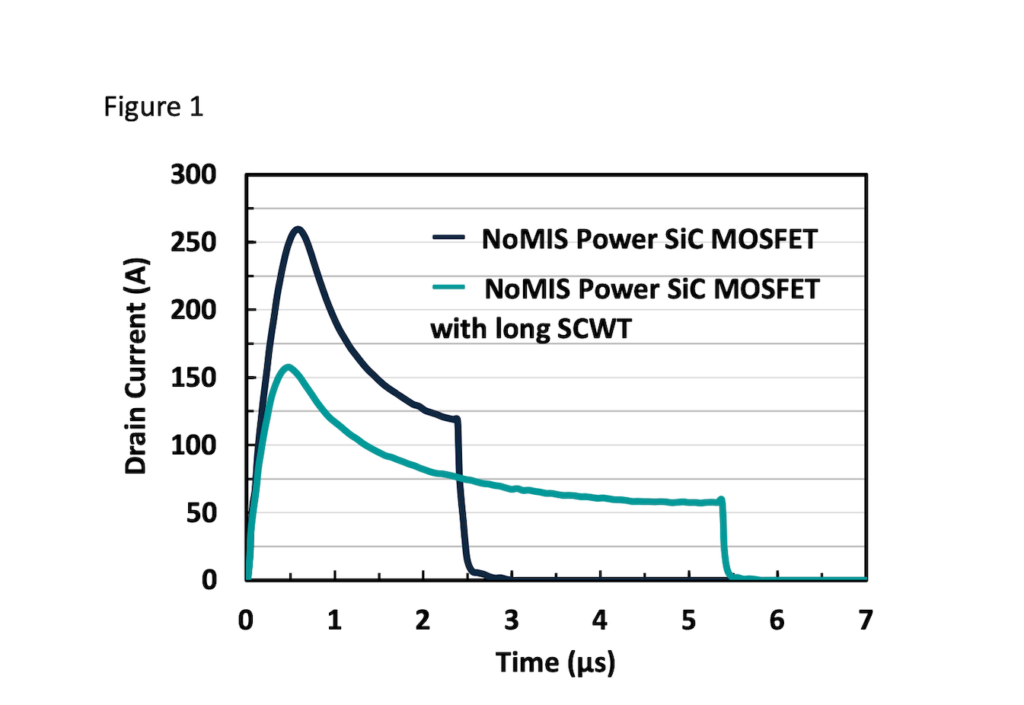

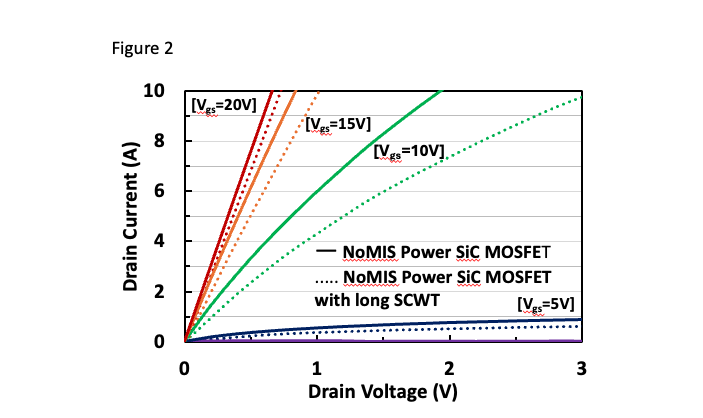

Silicon carbide (SiC) devices have gained prominence in power electronics due to their high efficiency, fast switching, and superior thermal performance. However, their historically lower short-circuit robustness compared to silicon-based IGBTs has posed challenges for their use in high-voltage and high-reliability environments, such as industrial drives, electric vehicles, and grid applications. NoMIS Power’s latest advancement significantly extends the SCWT of SiC MOSFETs to a minimum of 5 µs (Fig. 1), compared to the current industry standard of 2-3 µs, with no deleterious effect on specific on-resistance (Ron,sp) (Fig. 2). This enhancement greatly improves reliability and unlocks new opportunities for system designers seeking to maximize performance while maintaining fault tolerance.

Figure 1: Drain currents of the NoMIS Power SiC MOSFET and NoMIS Power SiC MOSFET with long SCWT under short-circuit conditions right before failure. Drain currents of the 1.2 kV, 80 mΩ SiC MOSFET (dark blue) and the long SCWT 1.2 kV, 80 mΩ SiC MOSFET (light blue) from NoMIS Power are compared. The measurement for short-circuit was conducted under the following conditions: Rg of 20 Ω, Vgs of 20 V, and a Vds of 800 V.

By tuning the trade-off between Ron,sp and SCWT using NoMIS Power’s proprietary SiC MOSFET fabrication design and process flow, the performance shown in Fig. 1 & Fig. 2 was achieved; and can be similarly managed depending on the specific application. Complete optimization of SiC MOSFETs with long SCWT using this approach will allow NoMIS Power to further extend the SCWT while maintaining negligible impact on Ron,sp.

Figure 2: Typical output characteristics of NoMIS Power 1.2 kV, 80 mQ SiC MOSFET and NoMIS Power 1.2 kV, 80 mQ SiC MOSFET with long SCWT showing no significant negative impact on on-resistance.

“At NoMIS Power, we have focused extensively on device architecture engineering, leading to a significant advancement in SiC short-circuit withstand time,” said Woongje Sung, CTO at NoMIS Power. “We believe this achievement provides valuable advantages to the power electronics community, helping engineers integrate SiC solutions with greater confidence in applications where robustness is critical.”

NoMIS Power’s long SCWT devices are well-screened for latent defects and offer easier gate driver desaturation (dSat) design for high di/dt and dv/dt, enabling faster switching frequencies of up to hundreds of kHz. Initial test results demonstrate a 2X to 4X increase in short-circuit withstand time compared to existing SiC devices, positioning NoMIS Power’s technology as a frontrunner in the next generation of power semiconductors. Additionally, when coupled with packaging innovations that impact junction-to-case thermal capacitance, alongside novel thermal management techniques with high heat transfer coefficients, the overall SCWT of the SiC MOSFET can be further improved.

The impact of this innovation extends across multiple industries, including renewable energy, electric transportation, and high-power industrial applications. A longer short-circuit withstand time ensures rugged and reliable performance in critical applications, reinforcing the robustness of SiC-based power systems. For example, built-in redundancy of the SiC MOSFETs inside power converters, which impacts costs as well as power density, can be reduced. Furthermore, applications sensitive to electromagnetic inference, that cannot solely rely on digital control and sensing schemes to detect and act upon short-circuit events, will now be able to effectively utilize SiC MOSFETs with lower risk. As SiC adoption accelerates, NoMIS Power’s breakthrough will play a pivotal role in enhancing the reliability and safety of SiC-based power converters and systems.

NoMIS Power is showcasing this breakthrough technology at APEC 2025, March 16-20, Atlanta, GA, Booth 548 along with its expanded range of SiC discretes and power modules.

Original – NoMIS Power

-

GaN / LATEST NEWS / WBG2 Min Read

Wise-integration will unveil its latest WiseGan® and WiseWare® advancements at APEC 2025 in Atlanta, featuring two technical presentations and demonstration boards, including a new 1.5kW Totem Pole PFC module designed specifically for server and industrial applications.

“GaN technology continues to drive new efficiencies in power electronics, and APEC 2025 is the ideal platform to showcase our latest advancements,” said Thierry Bouchet, CEO of Wise-integration. “Our WiseWare® digital controllers are accelerating the adoption of GaN by enabling higher performance, system simplification, and seamless integration. Beyond efficiency, they lay the foundation for the next generation of intelligent power systems, addressing the growing demands of AI-driven server and industrial applications. These innovations are re-shaping the future of power conversion.”

Presentations

Technical Session (T04.4): “Novel Dual Output LDO Architecture in 650-V GaN Technology for Power ICs”

- Speaker: Plinio Bau, IC Design Engineer

- Date/Time: Tuesday, March 18, 9:30 – 9:50 AM

- Overview: Introduction of a novel dual-output, low-dropout regulator (LDO) architecture designed for 650-V GaN technology to enhance power IC efficiency and performance.

Industrial Session (IS26): “Comparing ZVS Losses Distribution of Similar High-Performance GaN HEMTs”

- Speaker: Theo Simon, Power Electronics Application Engineer

- Date/Time: Thursday, March 20, 11:00 – 11:25 AM

- Overview: Analysis of zero-voltage switching (ZVS) loss distribution in high-performance GaN high-electron-mobility transistors (HEMTs) to optimize power conversion efficiency.

Live Demonstrations at Booth #1238: Wise-integration will showcase four state-of-the-art boards, featuring its latest WiseWare® technologies:

- 1.5kW Single-Phase Totem Pole PFC (CrCM) – Designed for server and industrial applications, powered by WiseWare® digital control, with switching frequencies from 200 kHz to 730 kHz,

- 300W Totem Pole PFC (CrCM) – Highlights GaN’s efficiency in power conversion using the WIW1101 MCU Digital Controller and WiseGan® WI71060A,

- 300W Totem Pole PFC (CrCM)-LLC – Demonstrates improved PFC-LLC performance with WIW1101 MCU Digital Controller, WiseGan® WI71060A (PFC), and WI71120A (LLC), and

- 150W WiseWare® 2 Demo Board – Showcases a patented single-stage architecture that virtualizes power factor correction (PFC), significantly simplifying system designAbout WiseWare® Digital ControllerWiseWare® is a high-frequency digital AC-DC controller portfolio for SMPS applications. Utilizing MCU-based ZVS proprietary firmware, it optimizes GaN transistor power conversion. WiseWare® 1.1 (WIW1101) is a digital controller for Totem Pole PFC in AC-DC converters, enabling CrCM operation with ZVS to maximize efficiency.

Original – Wise-integration

-

ALLOS Semiconductors and Canadian specialty semiconductor and performance materials supplier 5N Plus Inc. have announced the acquisition of the GaN IP portfolio from 5N Plus’ subsidiary AZUR Space Solar Power.

This strategic acquisition includes the buy-back of the GaN-on-Si technology for high power electronics (HPE) applications, which was originally sold to AZUR in 2020, along with several jointly completed innovations and resulting patent applications. With this acquisition, the global IP portfolio has expanded to over 50 granted patents, with more to come, most of them essential for both GaN-on-Si for optoelectronics and HPE applications. The transaction also includes the return of all recipes and other know-how.

This acquisition strengthens ALLOS’ position in the rapidly evolving areas of micro-LED displays and optical interconnect. ALLOS’ GaN-on-Si epiwafers are crucial for the customers to utilize standard silicon fabs for micro-LED manufacturing.

Additionally, this acquisition provides ALLOS’ with the option to re-enter the GaN-on-Si high power electronics (HPE) market. Power GaN has become a global mass market success and is projected to grow to over two billion USD by 2029. The unique features of ALLOS’ 200 mm and 300 mm technology can significantly benefit in scaling up production while reducing unit costs. In addition to standard silicon fab compatibility, these features include highest crystal quality, best wafer uniformity, and award-winning breakdown voltages for undoped GaN. While ALLOS remains focused on micro-LEDs, the company is now open to collaborations with HPE players.

Original – ALLOS Semiconductors

-

GaN / LATEST NEWS / WBG4 Min Read

Cambridge GaN Devices will demonstrate at APEC that the company’s ICeGaN® GaN ICs can now satisfy a broad range of applications with higher power requirements, such as servers, data centres, inverters, industrial power supplies and, very soon, automotive EVs over100 kW. The company’s new P2 series ICs feature RDS(on) levels down to 25 mΩ, supporting multi kW power levels with the highest efficiency, and a secure supply chain is in place including manufacturing deals with TSMC and ASE, and distribution through Digi-Key.

HENRYK DABROWSKI | SENIOR VICE PRESIDENT OF GLOBAL SALES, CGD

“GaN is now widely accepted as the technology of choice for mobile device chargers and is now set to supersede traditional silicon MOSFETs in higher power applications. The industry is also beginning to realize that GaN may replace SiC in certain high efficiency designs, due to its lower manufacturing cost. At APEC – one of the world’s most important events for the power industry – we are eagerly looking forward to having in-depth discussions with designers of high efficiency power systems and demonstrating the ruggedness, reliability and ease of use of our ICeGaN® GaN IC technology.”

During APEC, CGD will give the following Industry Session and Exhibitor Presentations:

Unlocking the Potential of Multi-level Inverters with Integrated ICeGaN technologies (Session: IS14.7)

As the electric vehicle market develops, there is a continuous drive to look at new and novel approaches to further improve the efficiency of the traction inverter and other electrical subsystems.Multi-level inverters enable the use of much high switching frequencies and break down the total voltage into smaller steps, which in turn allows for improved efficiency and downsizing of other parts of the system. GaN technology optimizes the benefits of multi-level topologies. CGD’s ICeGaN technology brings a higher level of integration, lower cost, best in class robustness and ease of use.

Presenter: Daniel Murphy, Director of Technical Marketing, CGD Date: Wednesday March 19, 2025 Time: 4:30 PM – 4:55 PM ET Location: Level Four, A411

ICeGaN Leads the Industry in GaN Integration

This presentation will demonstrate how ICeGaN technology leads in simplification, cost reduction, robustness, carbon footprint and efficiency of GaN power applications.Presenter: Peter Di Maso, Vice President, Business Development, CGD Date: Wednesday, March 19, 2025 Time: 12:45 PM – 1:15 PM ET Location: A301

On booth 2039, CGD will present demos that highlight the benefits of employing its ICeGaN technology in three application spaces: Motor Drives

- ICeGaN vs discrete GaN circuits comparison in half-bridge (daughter cards) demo board

- High and low power QORVO motor drive evaluation kits utilising ICeGaN and developed in collaboration with CGD

- Half-bridge built using CGD’s ICeGaN ICs in the BHDFN (Bottom Heat-spreader DFN) bottom-side cooled package with wettable flanks for easy inspection

Data Centres

- 3 kW totem-pole PFC evaluation board

- Half-bridge built using CGD’s BHDFN-packaged ICeGaN ICs

- Full-bridge demo showing CGD’s ICeGaN ICs in the DHDFN (Dual Heat-spreader DFN) package which has low thermal resistance (Rth(JC)), and can be operated with bottom-side, top-side and dual-side cooling. This package offers flexibility in design and out-performs the often-used TOLT package in top-side and, especially, dual-side cooled configurations.

- 2.5kW GaN-based CCM totem-pole PFC reference design targetting LED drivers, industrial brick DC/DC and general PSUs with power range of 500W to 1.5kW.

Scalable Power

- New single IC ICeGaN technology platform that delivers over 100kW, enabling CGD to address the $10B+ EV market, currently dominated by SiC, with cost-effective GaN solutions

- Single leg of a 3-phase 800 V automotive inverter demo board, developed in partnership with French public R&I institute, IFP Energies nouvelles (IFPEN)

- Parallel evaluation board demoing ICeGaN’s higher power capabilities

- Full-bridge demo showing CGD’s ICeGaN ICs in the DHDFN package

GIORGIA LONGOBARDI | FOUNDER AND CEO, CGD

“This is an exciting time for our industry as it embraces the disruptive GaN technology. Although this change from silicon has indisputably shown the power density and efficiency benefits of GaN, only CGD is presenting this new technology in an easy-to-use solution, which has been proven to be the most rugged in the industry. With our technology roadmap which details how ICeGaN will be able to address even EV applications over 100kW, we are sure designers will be inspired by the possibilities that ICeGaN has opened up.”

Original – Cambridge GaN Devices

-

GaN / LATEST NEWS / WBG3 Min Read

ROHM has announced that the EcoGaN™ series of 650V GaN HEMTs in the TOLL package has been adopted for AI server power supplies by Murata Power Solutions, a subsidiary of the Murata Manufacturing Group and a leading supplier of electronic components, batteries and power supplies in Japan. Integrating ROHM’s GaN HEMTs, which combine low loss operation with high-speed switching performance, in Murata Power Solutions’ 5.5kW AI server power supply unit achieves greater efficiency and miniaturization. Mass production of this power supply unit is set to begin in 2025.

Rapid advancements in IoT-related fields such as AI and AR (Augmented Reality) have led to a surge in global data traffic in recent years. Notably, the power consumption for a single AI-generated response is estimated to be several times higher than that of a standard Internet search, highlighting the need for more efficient AI power supplies. Meanwhile, GaN devices, known for low ON resistance and high-speed switching performance, are gaining attention for their ability to enhance power supply efficiency while reducing the size of peripheral components such as inductors used in power circuits.

Dr. Joe Liu, Technical Fellow, Murata Power Solutions

“We are pleased to have successfully designed AI server power supply units featuring higher efficiency and power density by incorporating ROHM’s GaN HEMTs. The high-speed switching capability, low parasitic capacitance, and zero reverse recovery characteristics of GaN HEMTs help minimize switching losses. This allows for higher operating frequencies in switching converters, reducing the size of magnetic components. ROHM’s GaN HEMTs deliver competitive performance and exceptional reliability, yielding excellent results in the development of Murata Power Solutions’ 5.5kW AI server power supply units. Going forward, we will continue our collaboration with ROHM, a leader in power semiconductors, to improve the efficiency of power supplies and address the social issue of increasing power demand.”

Yuhei Yamaguchi, General Manager, Power Stage Product Development Div., LSI Business Unit, ROHM Co., Ltd.

“We are delighted that ROHM’s EcoGaN™ products have been integrated into AI server power supply units from Murata Power Solutions, a global leader in power supplies. The GaN HEMTs used in this application provide industry-leading switching performance in a high heat dissipation TOLL package, enhancing power density and efficiency in Murata Power Solutions’ power supply units. We look forward to strengthening our partnership with Murata Manufacturing, a company that shares the similar vision of contributing to society through electronics – promoting the miniaturization and efficiency of power supplies to enrich people’s lives.”

Original – ROHM